| 領域 | 展覽 | 技術單位 | 技術名稱 | 詳細介紹 | 單項預約 | 多項預約 | 收藏 |

|---|

| 技術名稱 |

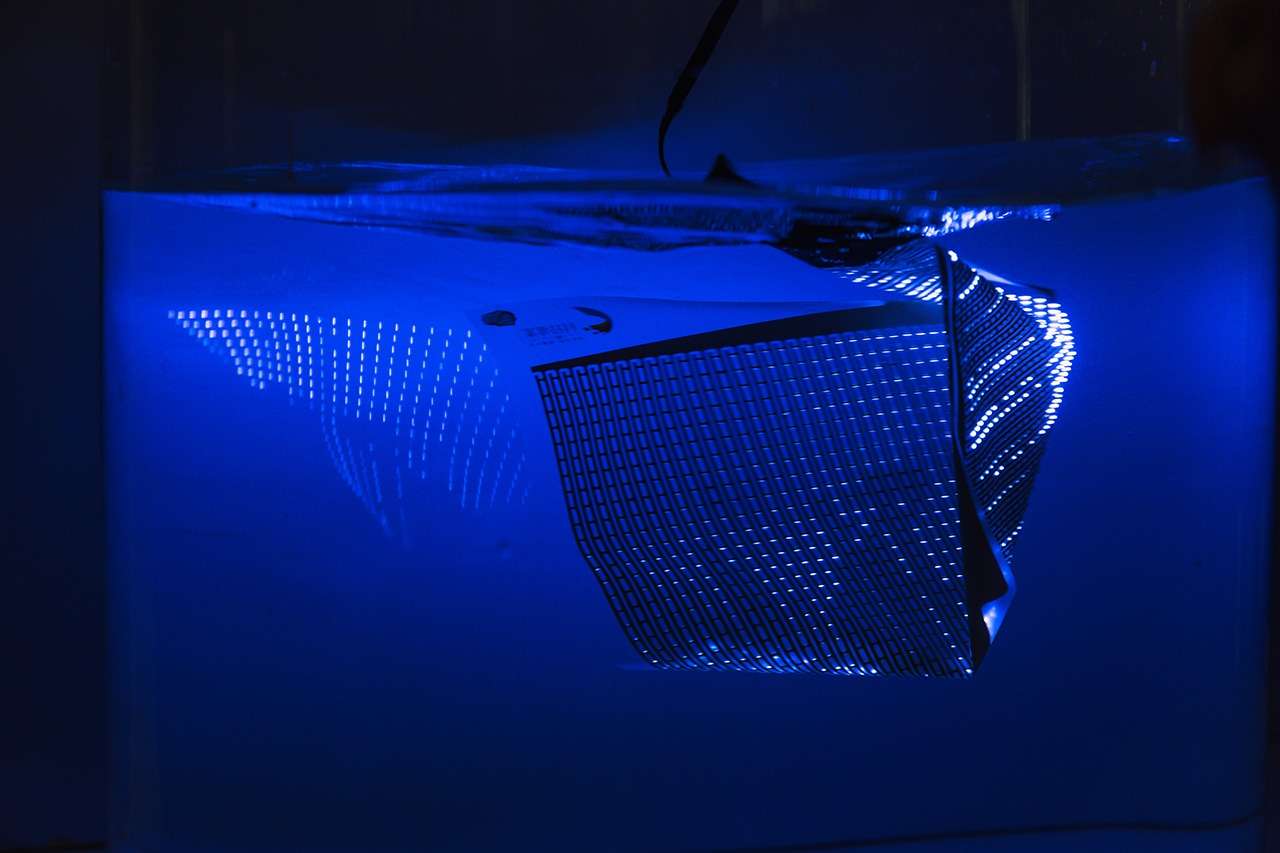

高溫耐腐蝕之化合物半導體製程用載盤 High Temperature and Anti-corrosion Compound Semiconductor Process Carrier |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan |

同步國際!第三代半導體製程載盤自主化 In sync with the world- Autonomy for the 3rd generation semiconductor manufacturing carriers |

| 技術簡介與應用 |

第三代半導體是臺灣重要產業策略,但製程載盤供應仍以國外為主,高溫耐腐蝕之化合物半導體製程用載盤技術,是國內唯一可供CVD SiC載盤製程,膜層平均厚度100±35μm、翹曲度小於500μm,不僅完整臺灣自主競爭力,更可大幅提高元件磊晶之品質。 The 3rd generation semiconductor is a critical industry strategy for Taiwan. However, the supply of manufacturing carriers mainly rely on foreign sources. The carrier technology for high-temperature corrosion-resistant compound semiconductor manufacturing is the only applicable domestic technology for CVD SiC carrier production. With an average film thickness of 100±35μm and warpage less than 500μm, this technology completes the autonomy and competitiveness of Taiwan and massively enhances the epitaxy quality of components. |

| 技術特點 |

・國內唯一SiC載盤技術・載盤壽命增加 ・元件磊晶品質優於國際 ・The only domestic SiC carrier technique・Increases carrier life ・The epitaxy quality of components surpasses the international level |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

二氧化碳合成高值樹脂(環碳酸酯)與應用技術 Preparation and Application of CO₂-based Cyclic Carbonate Resin |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan |

碳捕集!CO₂創造環保材料新商機 Carbon Capture - new business opportunities for eco-friendly materials from CO2 |

| 技術簡介與應用 |

負碳技術捕捉的CO₂搖身變成環保化學品。結合CO₂與環氧樹脂的新型聚氨酯樹脂材料,可應用於環保聚氨酯產品,打造CO₂為中心的碳源循環經濟。 已完成噸級生產技術開發,建立全球唯一多功能環碳酸酯單體產能,並降低生產成本少於每公斤3美元,帶動國內環氧樹脂產業高值應用。 The CO₂ captured by negative emission technologies turns into eco-friendly chemicals. The new polyurethane material combines CO₂ and epoxy for eco-friendly polyurethane products to build a carbon source circular economy centered by CO₂. The ton-level production technology has been developed to establish the world's only production capacity of multi-functional cyclic carbonate ester monomer. It reduces production costs to less than 3 USD per kg to facilitate the high-value applications of the domestic epoxy industry. |

| 技術特點 |

・以捕獲CO₂為原料・安全無毒・非異氰酸酯材料 ・Use captured CO₂ as materials・Safe, non-toxic・Non-isocyanate material |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

二氧化碳合成低碳排甲醇技術 Production of Methanol from CO₂ with Low Carbon Emission |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan |

減碳再升級!CO₂合成甲醇打造低碳產業鏈 For further carbon reduction - Low-carbon industrial chain built by CO2-converted methanol |

| 技術簡介與應用 |

二氧化碳變資源。以CO₂為原料,合成為工業廣泛使用的甲醇,應用於下游低碳化學品,建構國內低碳產業鏈,打造綠色競爭力。 本技術具高生產力,產量達1,000g克甲醇/小時.公斤觸媒,已達商業量產要求,操作溫度低可節能20%、具低成本生產優勢。 Methanol, commonly used in industry, can be synthesized using CO₂ as raw material to apply in downstream low-carbon chemicals, establish a domestic low-carbon industrial chain, and create a green competitivity. This technology has high productibility at 1000g methanol/hour per kg of catalyst, which is the requirement for general commercialization. The low operating temperature can also save energy by 20% to provide an advantage of low production costs. |

| 技術特點 |

・以捕獲CO₂為原料・生產節能20%・每小時噸級產量 ・Use captured CO₂ as materials・Saving 20% of energy in production・Ton-level production per hour |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

B4C陶瓷抗彈鎧甲 B4C Ballistic Ceramic Armor |

| 技術單位 |

國家中山科學研究院 National Chung-Shan Institute of Science and Technology |

| 隸屬部門 |

材電所 |

| 團隊名稱 | |

| 技術 Slogan |

通過國際認證的輕量防彈材料 Internationally certified lightweight bulletproof material |

| 技術簡介與應用 |

抗高速撞擊B4C基輕質陶瓷複材相較一般陶瓷複材,重量減輕20%,防護力通過美國懷特實驗室 NIJ III、NIJ III+、NIJ IV級陶瓷複材防彈板驗證。除作為防彈衣、防彈公事包等各式防彈產品材料外,亦可用於防護耳罩、蛙鞋、牙材等需抗衝擊之品項。 In contrast with the typical ceramic composite, the impact-resistant B4C lightweight ceramic composite reduces 20% of the weight. Its protection performance received NIJ level III, III+, and IV certifications for ceramic bulletproof plates from the USA H.P.WHITE laboratory. It can be the material of bulletproof products like bulletproof vests and suitcases or other impact-resistant products, such as protective earmuffs, scuba fins, and dental materials. |

| 技術特點 |

・輕量化耐衝擊陶瓷・國際認證防彈材料・防護領域應用首選 ・Lightweight impact-resistant ceramics・Internationally certified bulletproof material・Your first choice for protection applications |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

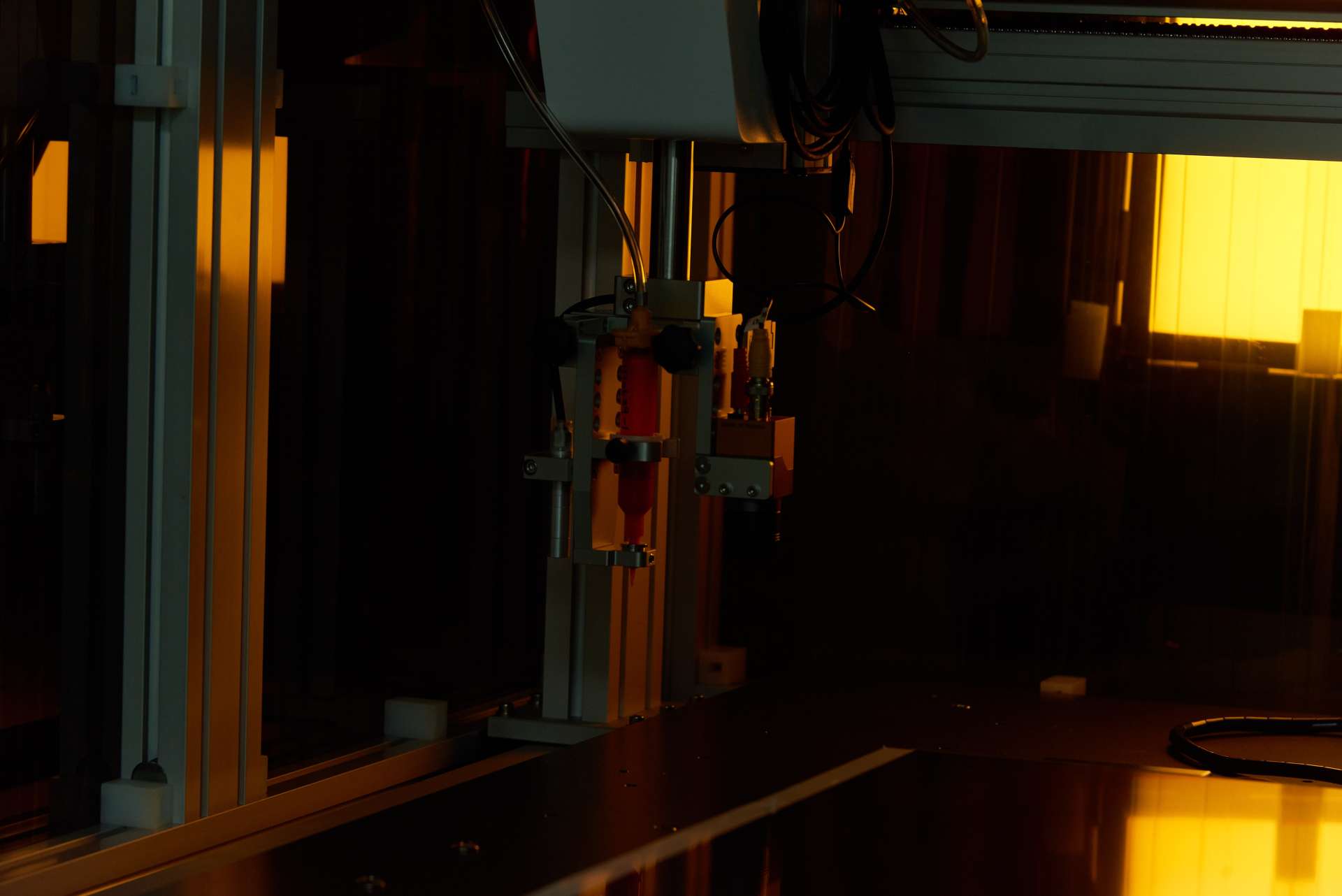

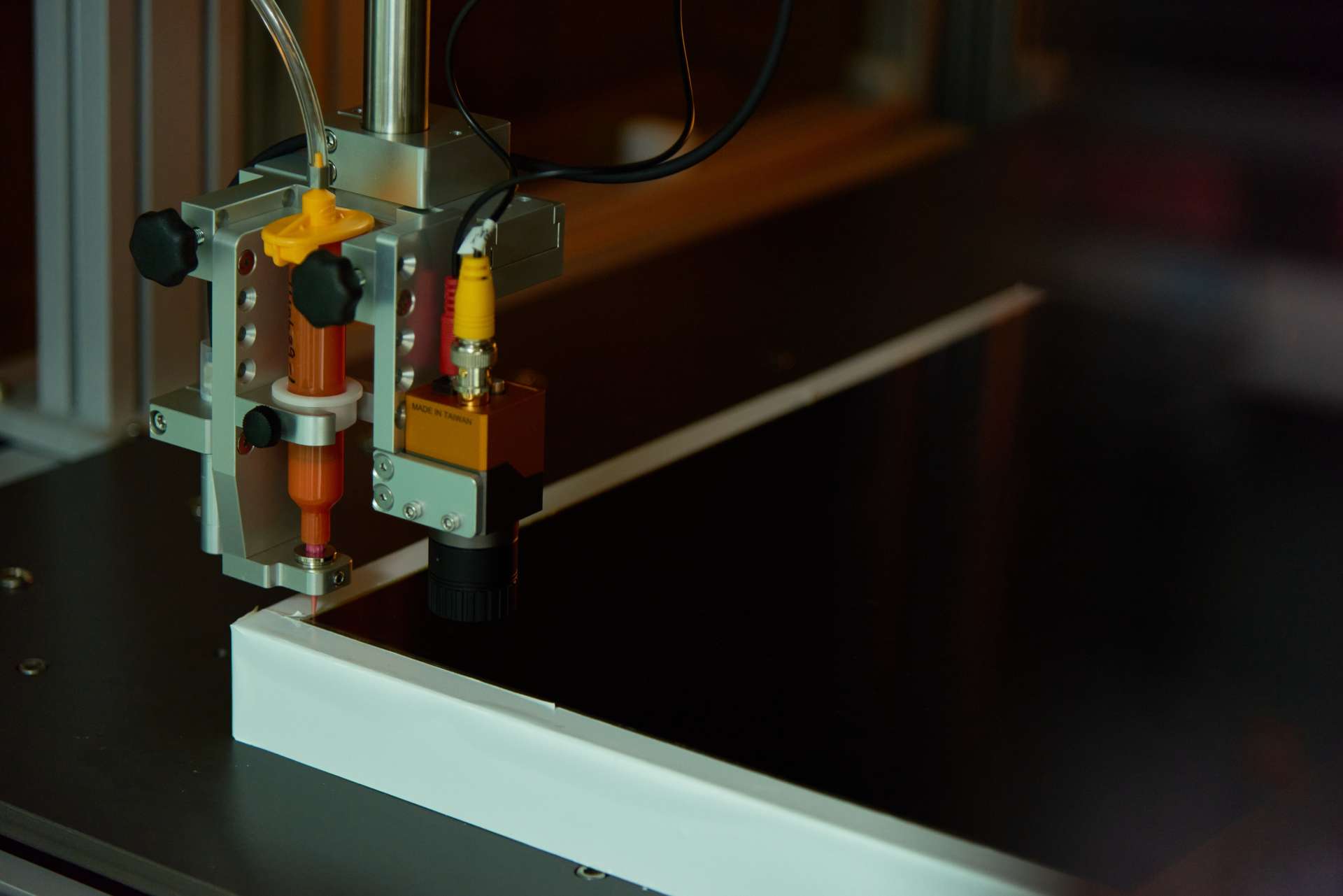

精準機能噴塗面料技術 Precise Inkjet Printing Technology for Fabrics |

| 技術單位 |

紡織產業綜合研究所 Taiwan Textile Research Institute |

| 隸屬部門 |

紡織所 |

| 團隊名稱 | |

| 技術 Slogan |

機能布料環保利器,染整業不再吃罰單 World's first Multi-vertebrae localization and guidance for spinal |

| 技術簡介與應用 |

透過精密分散研磨技術發展精準噴塗製程,開發高防水、高透濕、高透氣等機能性紡織品,從傳統塗布貼合優化至數位精準噴塗機能新面料,解決傳統染色製程耗水、耗能與化學品汙染問題,及整理製程在少量多樣化發展趨勢上的瓶頸。利用數位精準優勢,提供業者高彈性、短交期、低成本與互動設計之大量客製產銷模式。提升產品附加價值30%以上。 The precise spraying process is developed by the disperse milling technology for highly waterproof, permeable, and breathable functional textiles. It improves the process from traditional coating to digital precise spraying of new functional fabrics. This technology resolves the water consumption, power consumption, and chemical pollution problems for conventional dyeing processes and the difficulty of small-volume large-variety development for finishing processes. With the advantage of digital precision, this technology provides businesses with customized mass production and sales models with high flexibility, short delivery time, low cost, and interactive design to increase the additional values of products by over 30%. |

| 技術特點 |

・塗佈技術可複合應用・低耗水耗能・彈性客製化生產 ・Coating technology for complex applications・Low water and power consumption・Flexible customized production |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

超細長纖維不織布技術 Nonwoven Fabrics of Ultrafine Long Fibers |

| 技術單位 |

紡織產業綜合研究所 Taiwan Textile Research Institute |

| 隸屬部門 |

紡織所 |

| 團隊名稱 | |

| 技術 Slogan |

布可思議!超細長纖維不織布防蟎又阻菌 Dustmite and fungus-proof long-fiber non-woven cloth |

| 技術簡介與應用 |

掌握不織布原料關鍵技術,領先國際以「非溶除」分割型不織布開纖之環保製程,取代「溶劑」溶除型方式,並提升不織布纖維細化程度。 突破不織布原有物性能兼具機械強度與超細柔軟度,用途可從拋棄式衛材提升至寢具、人工皮革,及創新衣著面料。 Mastering the critical technology of non-woven cloths, we led the world by using the eco-friendly process of fiber opening for "non-dissolving" segmented non-woven textiles to replace the solvent-dissolving process to enhance the fineness of non-woven fabrics. This technology surpassed the physical properties of typical non-woven textiles, providing mechanical strength, extreme fineness, and softness. The applications range from disposable sanitary materials to beddings, artificial leathers, and innovative clothes fabrics. |

| 技術特點 |

・減少肌膚接觸不適・無溶劑更環保・細度0.5丹尼以下 ・Reduce contact discomfort of the skin・Solvent-free, more eco-friendly・Fineness < 0.5 denier |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

濱海場域耐候防蝕太電邊框新材料與應用技術 The New Material and Application Technology of Weather-resistant and Anti-corrosion solar photovoltaics frame in coastal field |

| 技術單位 |

錸德科技股份有限公司 RITEK Corporation |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan |

全天候高強度太電模組邊框非金屬複合材料 Novel non-metal composite material for solar module frames |

| 技術簡介與應用 |

為擴大沿海場域太陽能發電場域,並有效提供再生能源供企業使用,接軌國際綠色供應鏈。 增加太陽能板耐久性與可靠度。延長戶外太陽能板使用年限,及對抗濱海場域、岩灘、離岸等高濕高風壓高鹽害之嚴苛環境。 The durability and reliability of solar panels are improved to expand the fields for solar power in coastal areas, providing renewable energy efficiently for industries to help them get on track with the global green supply chain. The technology extends the service life of solar panels and provides resistance against humidity, wind, and salt in extreme environments, including coastal areas, rocky beaches, and offshore regions. |

| 技術特點 |

・耐候、抗侵蝕・環保回收低污染・增加綠能產能 ・Weather-resistant, corrosion-resistant・Eco-friendly, recyclable, low pollusion・Increases the production capacity of green energy |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

4D(3D+異質)固相式積層製造 4D (3D+Dissimilar) Printed of Solid State Process |

| 技術單位 |

金屬工業研究發展中心 METAL INDUSTRIES RESEARCH& DEVELOPMENT CENTRE |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan |

透過創新製造設計結合摩擦攪拌積層製造 Through innovative manufacturing design combined with friction stir additive manufacturing |

| 技術簡介與應用 |

將產品透過預先解析及設計成多個異質工件,以固相式的積層製造工法,進行異材接合及摩擦攪拌積層製造的製程,提供低成本且能同時能滿足多種特性的3D形狀金屬製品之創新製程,可運用在兼具燃料相容及機械強度特性的輕量化軌道衛星燃料桶槽製造上。 This technology can combine additive design of dissimilar metals through friction stir welding, and form various 3D structural dissimilar aluminum alloy parts through additive manufacturing method of solid state process. This technology can maintain the characteristics of the raw materials and complement the characteristics of dissimilar metals. |

| 技術特點 |

1.可進行異質材料接合2.減少加工材料3.加工設備門檻較低 1.Joining of dissimilar metals 2.Saving processing materials 3.Low threshold for processing equipment |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

再生多樣態轉化材 Renewable Polymorphic Transition Materials |

| 技術單位 |

金屬工業研究發展中心 METAL INDUSTRIES RESEARCH& DEVELOPMENT CENTRE |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan |

全循環及零廢棄 full recycling and zero waste |

| 技術簡介與應用 |

廢棄物循環再生轉化可用材料仿效鈣迴路自轉換邏輯,以碳酸鈣為轉化主體搭配二氧化矽,將反應路徑轉化為二大應用模式(工業鑄造、海洋復育),依不同終端產品調整不同製程,運用全回收材不僅維持鑄件強度,還解決傳統鑄造後殼模無法回收,以及達到產業廢棄物循環再生效益。 Poly-T Materials simulate the self-transit logic of calcium looping, where calcium carbonate is the main transit body that works with silicon dioxide and transits into two application modes based on the path of reaction, thereby regulating the process for exerting optimal properties of the product. |

| 技術特點 |

1.仿效鈣迴路的自轉換邏輯2.鑄造工業、海洋生態復育 3.首創全球創新綠色材料 1. the self-transit logic of calcium looping. 2.brand-new innovations in the casting industry and marine ecology restoration. 3.An innovative green material. |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

環保彈性導電漿料 An ECO Stretchable Conductive Ink |

| 技術單位 |

紡織產業綜合研究所 Taiwan Textile Research Institute |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan |

一種水洗與導電兼具的最佳解決方案 An optimal solution for both laundry and conductivity |

| 技術簡介與應用 |

1. 整合國內相關產業、國內自主生產,快速反應與價格競爭力 2. 改善電路板高污染性製程,減少環境污染與資源浪費 3. 提供新世代彈性電路板,可大批量生產 4. 可應用在各種產品表面上 1. Integrate domestic related industries, domestic independent production, quick response and price competitiveness 2. Improve the highly polluting process of circuit boards, reduce environmental pollution and waste of resources 3. Provide a new generation of flexible circuit boards, which can be mass-produced 4. Can be applied on various product surfaces |

| 技術特點 |

1. 可水洗高穩定性2. 可快速回收再利用3. 低碳環保 1. Washable and high stability2. Rapid recycling and reuse3. Low-carbon and environmentally friendly |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

超高純度多功能奈米矽粉體 High Purity Multi-Functional Nano Silicon |

| 技術單位 |

國立成功大學 National Cheng Kung University |

| 隸屬部門 | |

| 團隊名稱 |

Nano Silicon |

| 技術 Slogan |

超高純度多功能奈米矽粉體是搶手貨 High Purity Multi-functional Nano Silicon - The Hot Cake |

| 技術簡介與應用 |

超高純度多功能奈米矽粉體經由整合矽粉體微細化、粒徑分佈控制、粉體分散、氧化層厚度控制與粉體純化等技術進行量產 (1噸/月),用於製造高品質鋰離子電池所需矽基負極材料以及碳化矽半導體所需高純度碳化矽粉體之原料。 High purity multi-functional nano silicon powders are mass-produced (1 ton/month) for the application in high quality silicon-based anode materials for lithium ion battery and the high purity silicon carbide powder for silicon carbide semiconductor by integrating the technologies of silicon powder downsizing, size distribution control, powder dispersion, oxidation layer thickness control and powder purification. |

| 技術特點 |

1.低成本2.高純度3.用於製造高品質矽基負極材料和高純度碳化矽粉末 1.Low cost2.High purity3.Applied in high quality silicon-based anode materials and high purity silicon carbide powders |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

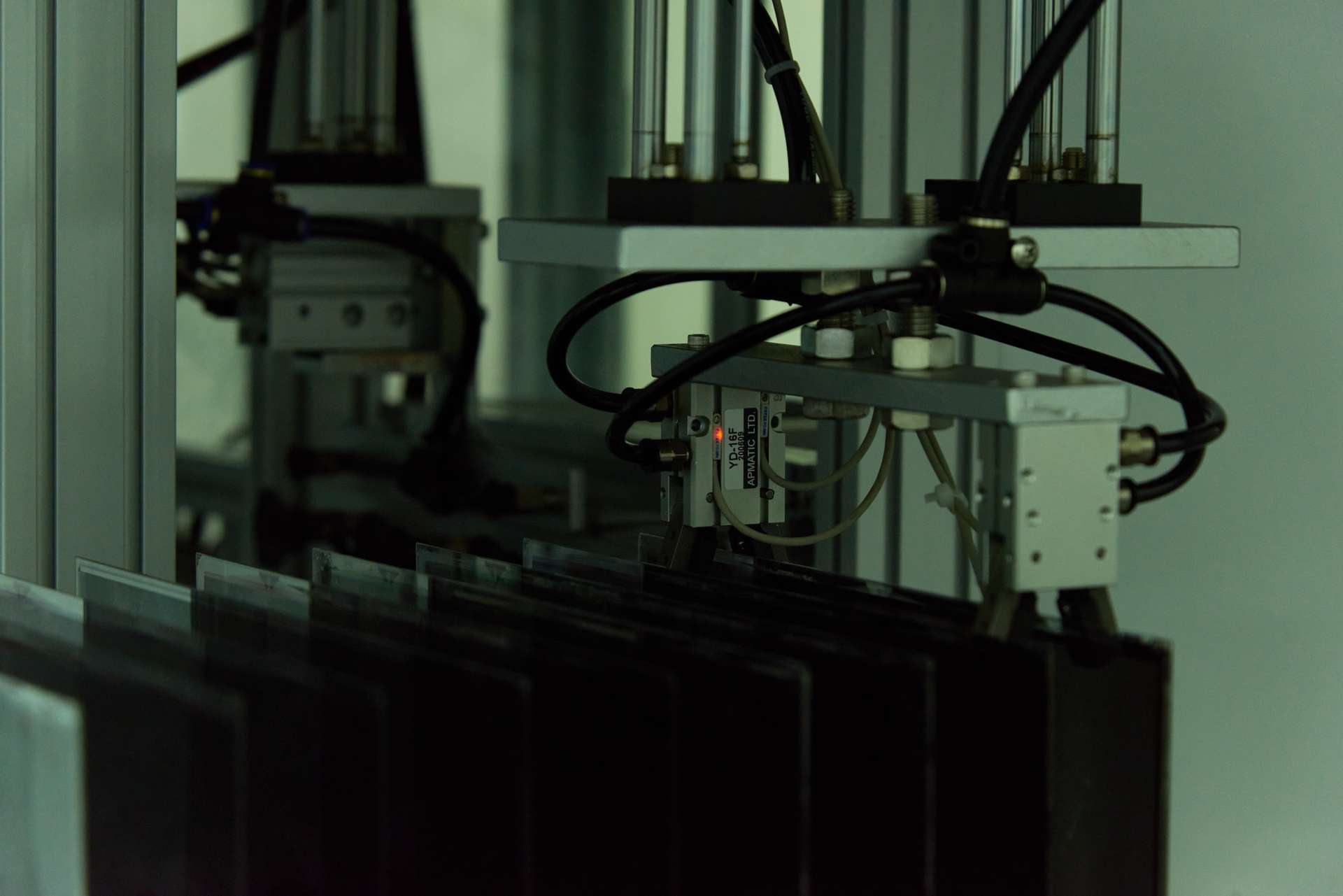

高接著雷射拆解封裝膠材料&面板非破片高價材料循環製程 Panel With Laser Debonding Sealant & Liquid Crystal Panel Non-fragmented High-priced Material Recycl |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

協助LCD廠將廠內不良品之組件及液晶材料循環利用,提升各項材料的循環應用價值。 建構全球首創易拆解面板材料與製程驗證線,加速面板業者符合循環規範要求,達到減廢、回用,同時帶動綠色循環供應鏈,大幅提升面板資源之循環使用率,使台灣成為綠色面板供應大國。 To enable LCD panel makers reuse NG products and LC. Increase the value of each material by recycling. Establishing the first material and process line for disassemable panel in the world. Asisting panel makers to meet the requirements of recycling and reducing waste. Increase the recycling rate of panel materials that makes Taiwan become the pioneer in green panel industry. |

| 技術特點 |

框膠可進行雷射拆解。面板組件非破片分離。組件材料重複拆解/組立。 Laser debonding sealant.Panel non-fragmentation separation.Repeated disassembly/assembly of components. |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

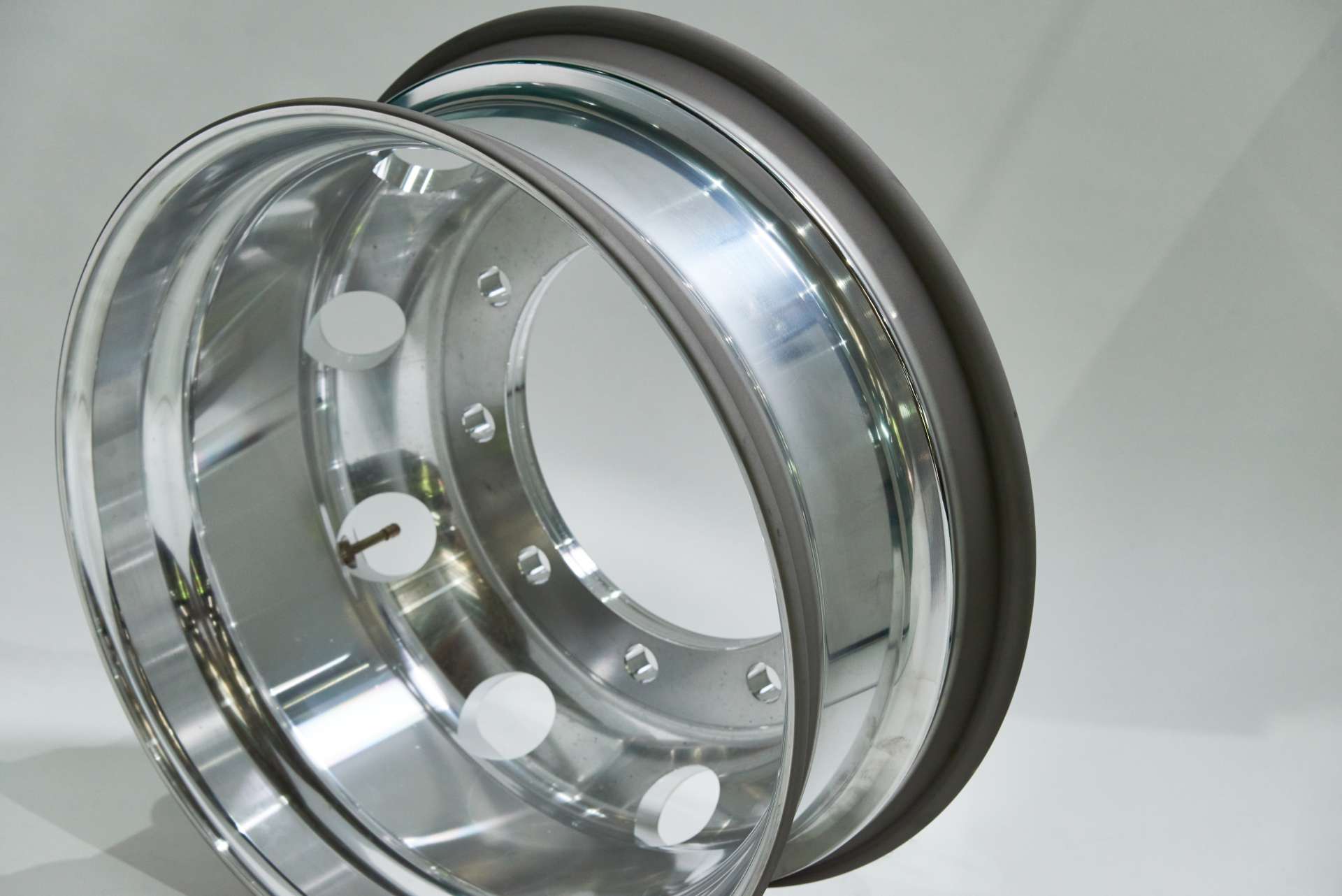

| 技術名稱 |

車用輕量化高性能鋁合金與複材技術 Lightweight and High-performance Aluminum Alloy and Composite Technology for Vehicles |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

輕量化汽車用高強度鋁合金複材,利用微奈米陶瓷顆粒強化鋁合金,解決鋁合金強度與硬度不足問題。開發出適當高強度鋁合金之複合材料組成配方,利用熱噴塗技術將鋁輪圈凸緣部分進行硬面處理後,硬度與耐磨耗性能大幅提高,大幅延長重車輪圈使用壽命。 The high-strength aluminum composite for lightweight automobiles uses micro-nano ceramic particles to strengthen aluminum, solving the problem of insufficient strength and hardness of aluminum alloys. Developed an appropriate high-strength aluminum composite formula, using thermal spraying technology to hard-face the aluminum rim flange part, the hardness and wear resistance are greatly improved, and the service life of heavy-duty wheel is greatly extended. |

| 技術特點 |

・取代鋼鐵零件達輕量化・陶瓷強化提高強硬度・使用壽命提高至少2倍以上 ・Reduce weight by replacing steel parts・Ceramic reinforcement improves strength and hardness・The service life is increased by more than 2 times |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

聚酯同質易回用-TPEE低熔點熱熔膠膜綠色貼合材料技術 Mono-material is Crucial for Recycling:TPEE Adhesive Hot Melt Technology |

| 技術單位 |

中華民國紡織業拓展會 |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

首創TPEE聚酯熱熔膠膜貼合材料,改質TPEE高熔點與熱流動性,增加彈性回復與黏合性能,提供具環保、彈性、不易水解的紡織貼合新材料,解決業界熱熔膠貼合造成溶劑殘留、易黃化、水解、不能回收的問題,提高紡織產品品質與耐久性,增加聚酯紡織品循環再利用效率。 Developing Thermoplastic Polyester Elastomer (TPEE) material that modified high melting point and thermal fluidity. It improves elastic recovery, and adhesive properties, and provides a new material that is eco-friendly, stretchable, and anti-hydrolysis. It can solve the problem of residue, easy yellowing, hydrolysis, and non-recycle. It can improve the quality and durability of textile products, and increases the recycling efficiency of polyester textiles. |

| 技術特點 |

‧聚酯同質貼合易回用‧環保安全、耐候性優‧貼合耐用、水洗不剝離 ‧Mono-material is crucial for recycling‧Environmental safety and good weather resistance‧Durable, no degumming after washing |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

高含浸技術暨熱塑碳纖複材加工製程整合平台 The Integration Platform of High Impregnation Technology and Carbon Fiber Thermoplastic Composite Processing Process |

| 技術單位 |

塑膠工業技術發展中心 Plastics Industry Development Center |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

熱塑複材技術能讓產品具備輕量化、高強度、高耐熱性以及循環再應用。同時,結合新加工製程導入,產品生產效率提升達三倍以上,大幅度降低產品生產成本,可廣泛應用於航太、國防、電動車等高階產業。 Thermoplastic composite technology can make products with lightweight, high strength, high heat resistance and recycling. Furthermore, combined with new processing processes, the production efficiency of products has been increased by more than three times, which can dramatically reduce the production cost of product. Importantly, thermoplastic composites can be widely used in high-end industries such as aerospace, national defense, and electric vehicles. |

| 技術特點 |

・產品重量減輕30%・生產效率提高3倍・加工製程簡易,成本低 ・30% reduction in product weight・Production efficiency increased by 3 times・Simple process and low cost |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

超臨界物理發泡技術 Supercritical Physical Foaming Technology |

| 技術單位 |

鞋類暨運動休閒科技研發中心 Footwear & Recreation Technology Research Institute |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

改善傳統化學架橋發泡產品不易循環使用之問題,結合熱可塑彈性體,以超臨界物理發泡方式,實現非架橋,且兼具可環保回收與高彈特性的輕量化技術。 應用本技術製造之發泡產品除了上述特性外,無化學殘留物、無VOC汙染等優點,更符合國際環保趨勢與品牌需求。 To solve the problem that the traditional chemical-foaming/cross-linked foams cannot be recycled, the physical foaming technology achieves the foamed thermoplastic elastomers without crosslinking. It owns excellent properties of recyclability, rebound and lightweight. Besides, it has the advantages such as non-chemical residues in the product and non-VOC pollution during processing, which meets to international environmental protection trends and brand needs. |

| 技術特點 |

(1)非架橋之物理發泡製程(2)熱熔後可回製成原料粒(3)回彈與輕量特性優異 (1) Non-crosslinking physical foaming process(2) Recycle raw pellets by melting(3) Excellent rebound and lightweight properties |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

高活性CO2甲烷化觸媒技術 High Activity CO2 Methanation Catalyst Technology |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan |

高效能觸媒與具熱回收之甲烷化系統 High performance catalyst and methanation system with heat recovery |

| 技術簡介與應用 |

1.觸媒具自主專利:採殼核結構,減少觸媒燒結失活;高效能觸媒,有效提高反應空間流速,提高生產力。 2.系統具移熱設計,控制觸媒床溫度≦ 400℃. 反應器設計彈性化:具熱回收設計,產生低壓蒸氣。 3. 產物甲烷濃度可達98%以上,可直接串接天然氣系統。 1. Catalyst with independent patent: high-efficiency catalyst can effectively increase the flow rate in the reaction space and improve productivity. 2. The system is designed with heat recovery to generate low-pressure steam. 3. The methane concentration of the product can reach more than 98%, which can be directly connected to the natural gas system in series |

| 技術特點 |

1.觸媒具自主專利2.反應器設計彈性化3.產物甲烷濃度達98%以上 1. The catalyst has its own patent.2. Reactor design flexibility.3. The methane concentration of the product is over 98% |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

高階碳纖維應用於並聯型機器手臂 Application of The Advanced Carbon Fiber in Delta Robot |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan |

同時滿足稼動率及節能需求之複合材料。 Composite materials that meet both utilization rate and energy saving requirements. |

| 技術簡介與應用 |

工研院開發的高階輕量化碳纖維複合材料(T1000),並導入奈米制振膜材,可降低機器手臂高速運轉時產生的振動,解決運轉振動衰減時間過長困擾,抓取速度從1次/2秒提昇至1次/1秒,產線效率提高50%,降低馬達驅動能耗更節能。 The vibration and long attenuation time problems caused by the back and forth high-speed motion of the delta robot can be reduced by using the technology including the advanced lightweight carbon fiber composite material(T1000) and nano-damping diaphragm materials developed by the Industrial Technology Research Institute. The grab interval was decreased from 2 sec/round to 1 sec/round, which can be considered as the production line efficiency was increased by 50%. At the same time the energy consumption of the motor drive is reduced to save energy. |

| 技術特點 |

1. 可有效低能耗提高為高階碳纖維(T1000)。2. 解決高阻尼與剛性的衝突限制。3. 所開發的碳纖維支臂之阻尼性質可被大幅提高。 1. The energy consumption of improving the mechanical performance to T-1000 grade is relatively low.2. The conflicting constraints of high damping and stiffness were solved.3. The damping properties of the developed carbon fiber robot arm can be significantly improved. |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

超低碳排新材料開發與鞋材應用評估 Development of Low Carbon Emission Polyester Elastomer and Shoe Application Technology |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan |

低碳可回收鞋技術,同時解決廢棄聚酯材料與廢棄鞋汙染問題 Low-carbon and recyclable shoe technology, while solving the pollution problems of waste polyester materials and waste shoes |

| 技術簡介與應用 |

新型rTPEE材料具有低碳排且優異的加工性,可取代無法回收的鞋中大底材料,並使全鞋材料趨向單一化。透過物理發泡與射出貼合製程能大幅降低全鞋碳排放量。透過共聚合結構與混煉配方設計,rTPEE可滿足鞋製造領域之需求。同時協助品牌商加速達到碳中和之目標。 The new rTPEE material has low carbon emissions and excellent processability, which can replace the shoes material of that cannot be recycled, and make the whole shoe material tend to be single. Through the physical foaming and injection molding process, the carbon emission of the whole shoe can be reduced too. rTPEE can meet the needs of the shoe manufacturing field. At the same time, it assists brand owners to accelerate the achievement of the goal of carbon neutrality. |

| 技術特點 |

・r-PET解聚與低碳rTPEE材料開發・超臨界射出發泡之高回彈輕量化中底・全鞋單一材料與可回收再製 ・Depolymerization of r-PET and development of low-carbon rTPEE materials・Supercritical injection foaming for high rebound and lightweight midsole・Single material and recyclable sports shoes |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

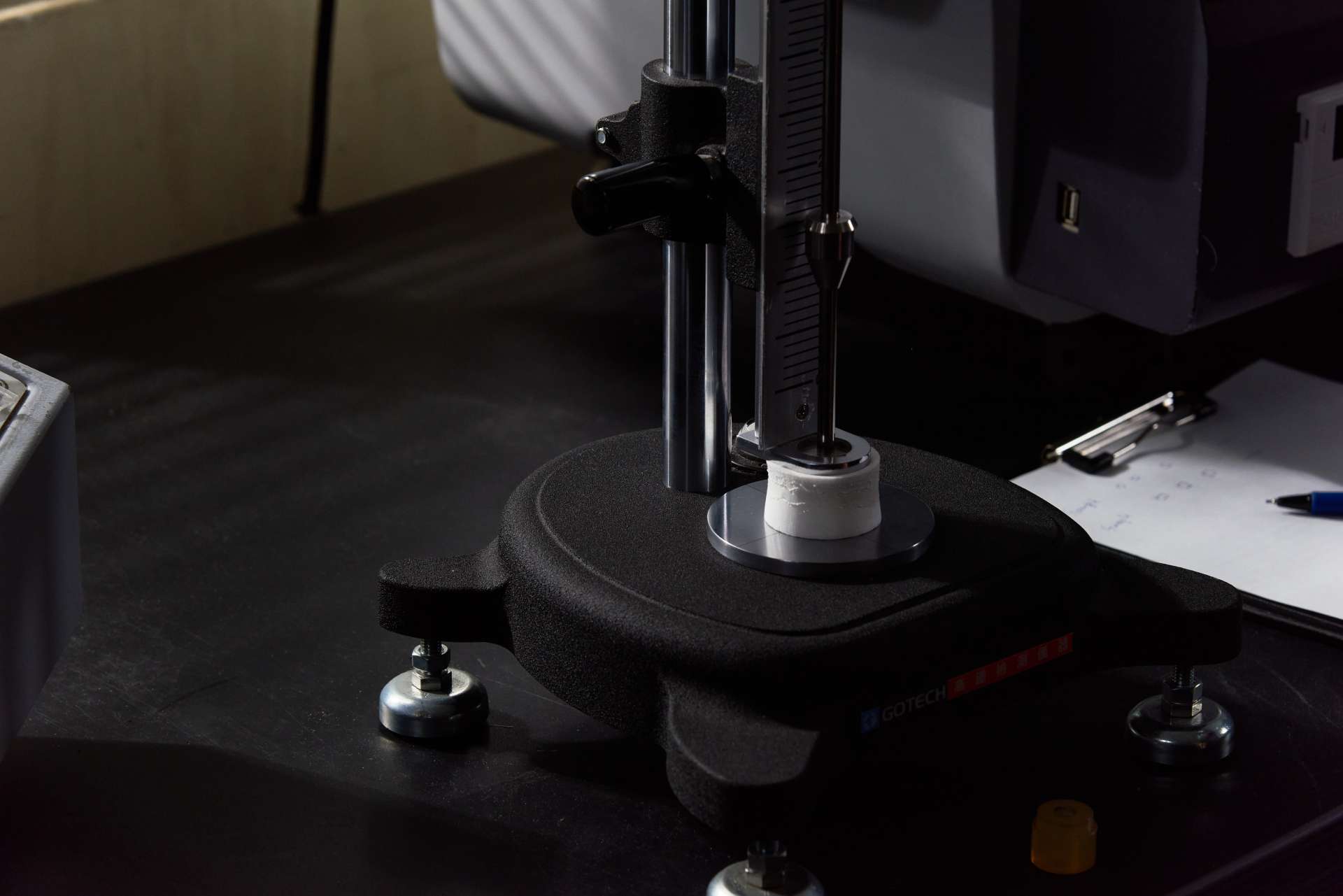

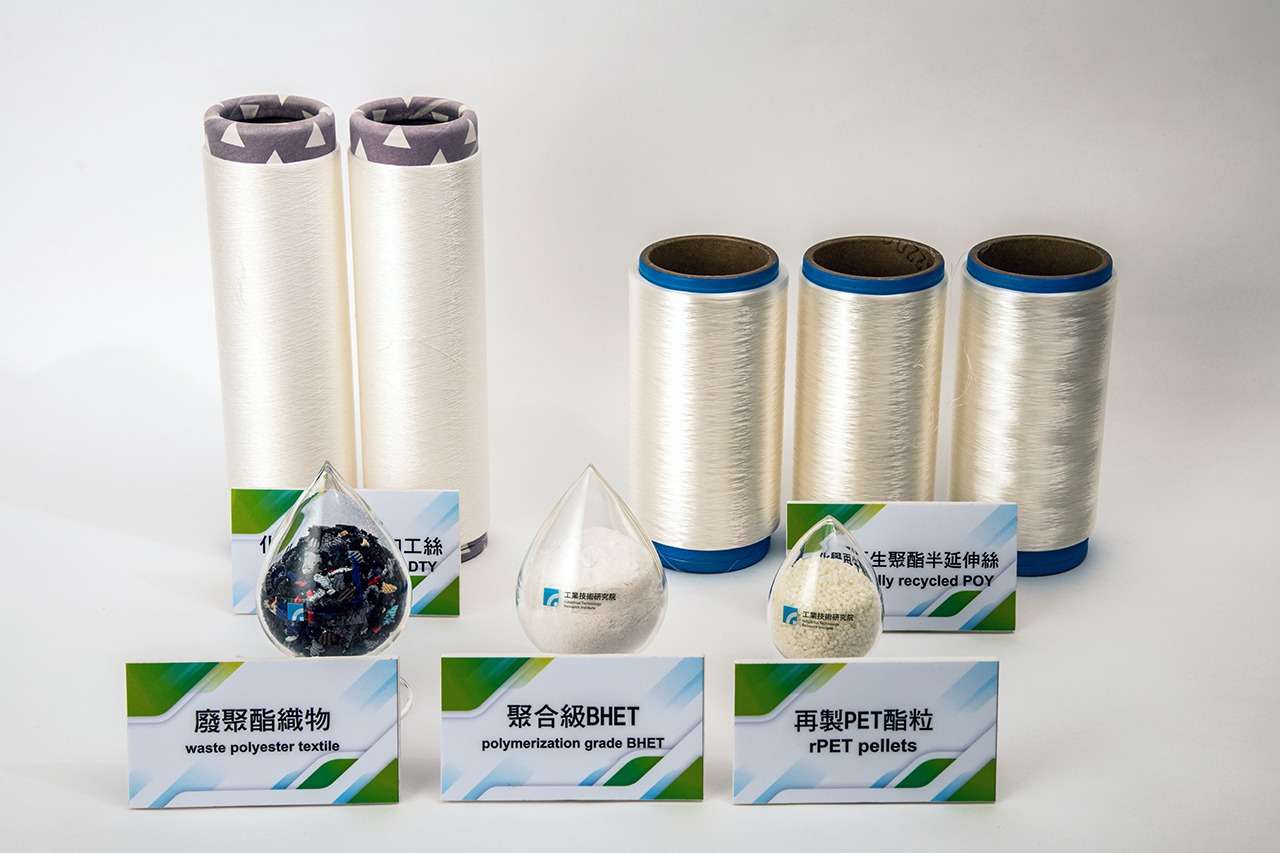

| 技術名稱 |

聚酯織物化學解聚與循環應用技術 Chemical Recycling Technology of Waste Polyester Textiles |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan |

廢織物再製高品質聚酯化學回收技術 Chemical recycling technology from waste textiles to high-quality polyesters |

| 技術簡介與應用 |

• 結合自主觸媒技術,並於製程端導入選擇性處理程序提高染料移除效率;透過製程整合設計與再結晶調控,可穩定製備高純度、低色度的BHET,再聚的PET特性能與石化新料相近。採用本技術之循環一次PET與最終焚化PET之碳足跡相比,可降低~60%碳排。 By integrating proprietary catalyst technology and incorporating selective treatment processes, the efficiency of dye removal is enhanced. Through process integration design and recrystallization control, production of high purity and low color BHET is achieved, and the properties of the repolymerized PET are comparable to virgin ones. The adoption of this technology in the recycling of PET significantly reduces the carbon footprint by approximately 60% compared to incinerating the PET waste after a single-use cycle. |

| 技術特點 |

低金屬溶出觸媒技術 高效除色之解聚製程 高品質、低色度再生單體 Catalyst with low metal dissolutionDepolymerization process with efficient decoloringHigh quality, low chroma recycled monomer |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

高純半絕緣型碳化矽粉體技術 High-Purity Semi-Insulating Silicon Carbide (SiC) Powder Technology |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan |

碳化矽半導體材料解決方案 A solution from SiC raw material to wafer |

| 技術簡介與應用 |

提升碳化矽粉體純度與晶粒尺寸,以符合國內業者對於長晶原材料之需求,可有效降低生產成本。 藉由粉體合成過程中同時達到提純與晶粒粗化之效果,不需額外進行提純之製程,減少廢氣與廢液之產生。 Enhancing the purity and grain size of silicon carbide powder to meet the requirements of domestic crystal growth material manufacturers can effectively reduce production costs. By achieving purification and grain coarsening simultaneously during the powder synthesis process, there is no need for additional purification processes, thereby reducing the generation of waste gas and waste liquid. |

| 技術特點 |

・碳化矽粉體粒度調控・碳化矽晶相調控・純度調控,適合長晶需求 ・Particle Size Control of Silicon Carbide Powder・Control of Silicon Carbide Crystal Phase・Purity Control for Crystal Growth Requirements |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

中空纖維CO2捕獲純化技術 Hollow Fiber Technique of CO2 Capture And Purification |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan |

節能捕碳新材料,淨零碳排更有效 New materials for energy-saving carbon capture, net zero carbon emissions are more effective. |

| 技術簡介與應用 |

中空纖維CO2捕獲材料的多層孔洞結購,具有高比表面積與氣流通道設計,可提升25~35%CO2吸附效率,降低操作壓力,節省設置空間,並降低系統操作成本。解決商用分子篩顆粒在操作上的缺點,利用更少的能源,捕獲更多CO2,進一步達到碳中和的目標。 The hollow fiber absorbent of CO2 capture material has multi-layer hole structure. It is high specific surface area and hollow channel design that can increase CO2 adsorption efficiency about 25~35%. The hollow fiber absorbent can decrease operating pressure, save installation space, and reduce system operating costs. Solving the operation problems of commercial molecular sieve particles, the hollow fiber absorbents can use less energy, capture more CO2, and achieve the goal of carbon neutrality. |

| 技術特點 |

(1).低壓損可減少操作能耗。(2).高比表面積降低設置成本。(3).無粉塵問題 (1)Low pressure drop reduces energy consumption.(2)High specific surface area reduces captical costs.(3)No dusting issue. |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

半導體合金鋁鈧金屬靶 Aluminum Scandium Alloy Sputtering Target in Semiconductor Application |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan |

高純度細晶鋁鈧合金靶材 High-purity and fine-grained aluminum-scandium alloy sputtering target |

| 技術簡介與應用 |

為解決關鍵材料鋁鈧合金靶材自主化生產的問題,本技術透過金屬鈧合成、純化、合金製靶等技術,提供國內靶材廠發展鋁鈧合金製靶技術。掌握關鍵靶材原物料來源及建立鋁鈧合金製靶成型核心技術。 In order to solve the problem of independent production of the key material aluminum-scandium alloy sputtering target, this technology provides Taiwan target factories with the development of aluminum-scandium sputtering target manufacturing method through metal scandium synthesis, purification, alloy sputtering target manufacturing method. Grasp the source of key target raw materials and establish the core technology of aluminum-scandium alloy target forming. |

| 技術特點 |

高純度細晶鋁鈧合金製靶技術本技術應用於5G/6G通訊用之濾波器元件全球鋁鈧靶產值約2.5億美元 High-purity and fine-grain aluminum-scandium alloy sputtering target manufacturing technology.This technology is applied to filter components for 5G/6G communication.The global aluminum scandium alloy sputtering target production value is about 250 million USD. |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|