| 領域 | 展覽 | 技術單位 | 技術名稱 | 詳細介紹 | 單項預約 | 多項預約 | 收藏 |

|---|

| 技術名稱 |

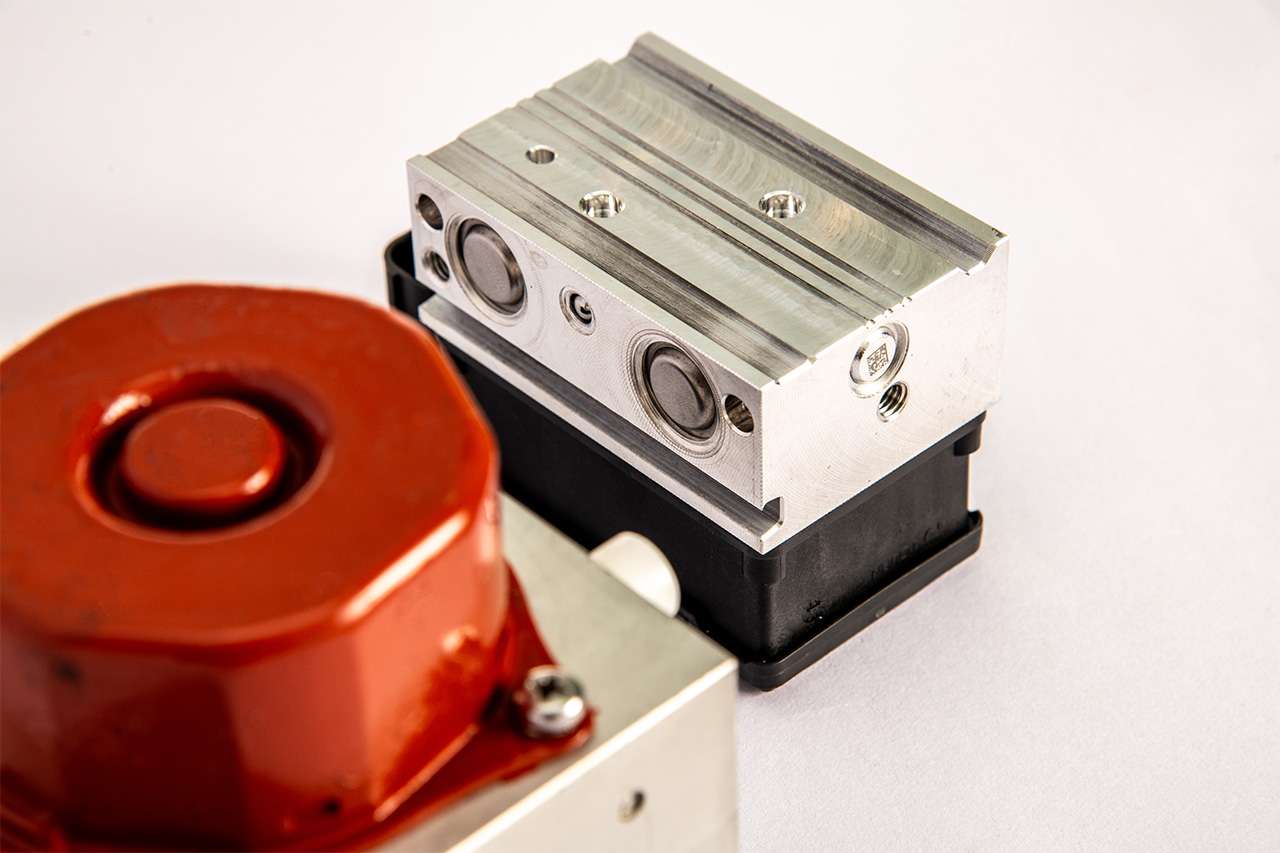

長航時燃料電池無人機 Long-Endurance Fuel Cell Powered UAV |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan |

功率密度領先國際!高續航/高酬載飛行專家 High endurance/ high load flight expert with world-leading power density |

| 技術簡介與應用 |

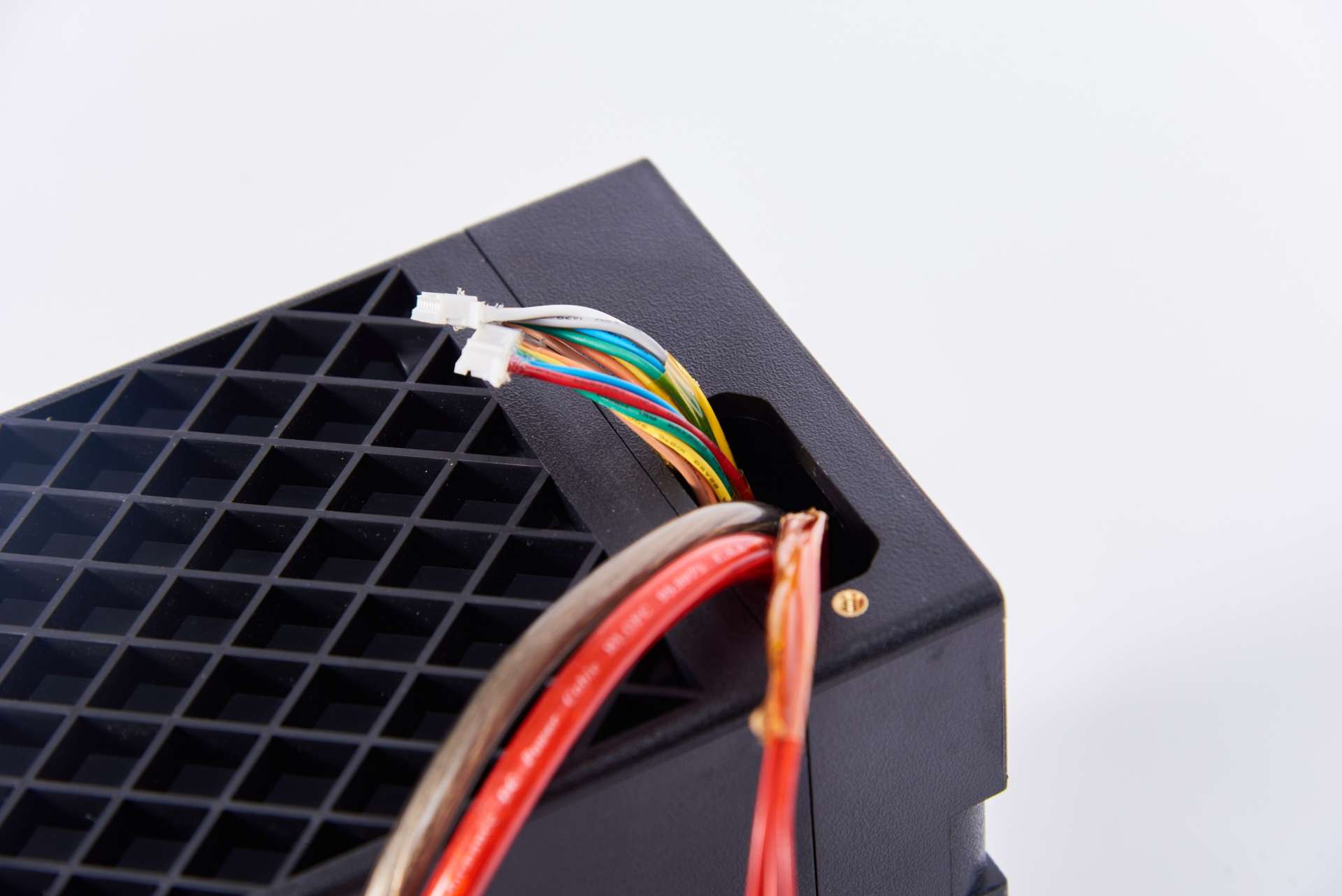

希望無人機飛得久又載得多,高能量燃料電池技術是長航時無人機的解答。通過逾400公里高山跨海負重飛行驗證及民航局特種實體檢驗之長航時燃料電池無人機,可提升無人機3倍的飛行時間,9倍的飛行區域,燃料電池之功率密度達1200W/kg也領先國際大廠。 High energy fuel cell technology is the solution for drones with long flight times, allowing them to fly longer and carry more. Powered by fuel cells, long flight time drones passed the 400 km high-altitude/cross-sea flight test and the CAA special inspection. It increases drone flight time by three times and flight range by nine times. The 1200 W/kg power density of fuel cells also leads international industries. |

| 技術特點 |

・3倍飛行時間・電堆功率密度1200W/kg・最大起飛重量30公斤 ・3-times longer flight time・Fuel cell stack power density 1200W/kg・Maximum Take-Off Weight 30kg |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

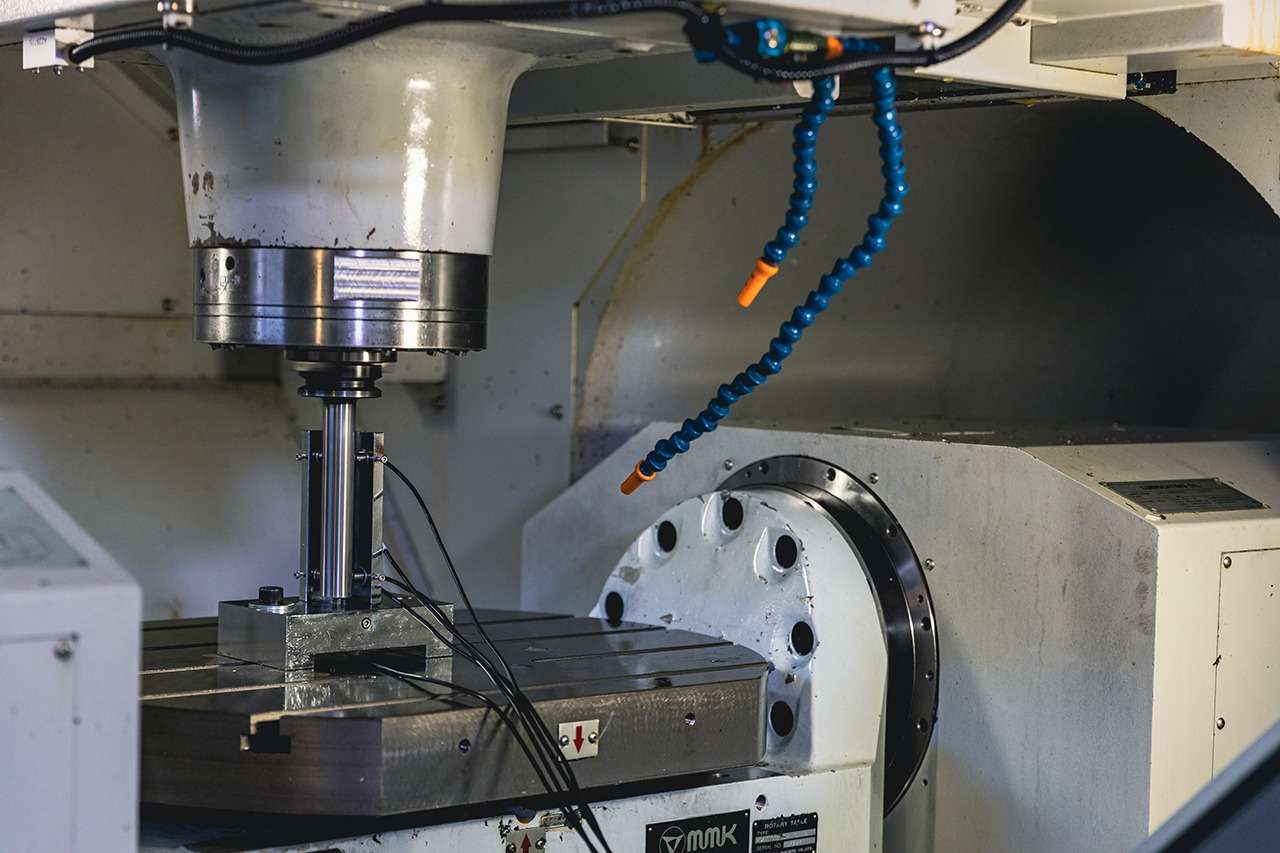

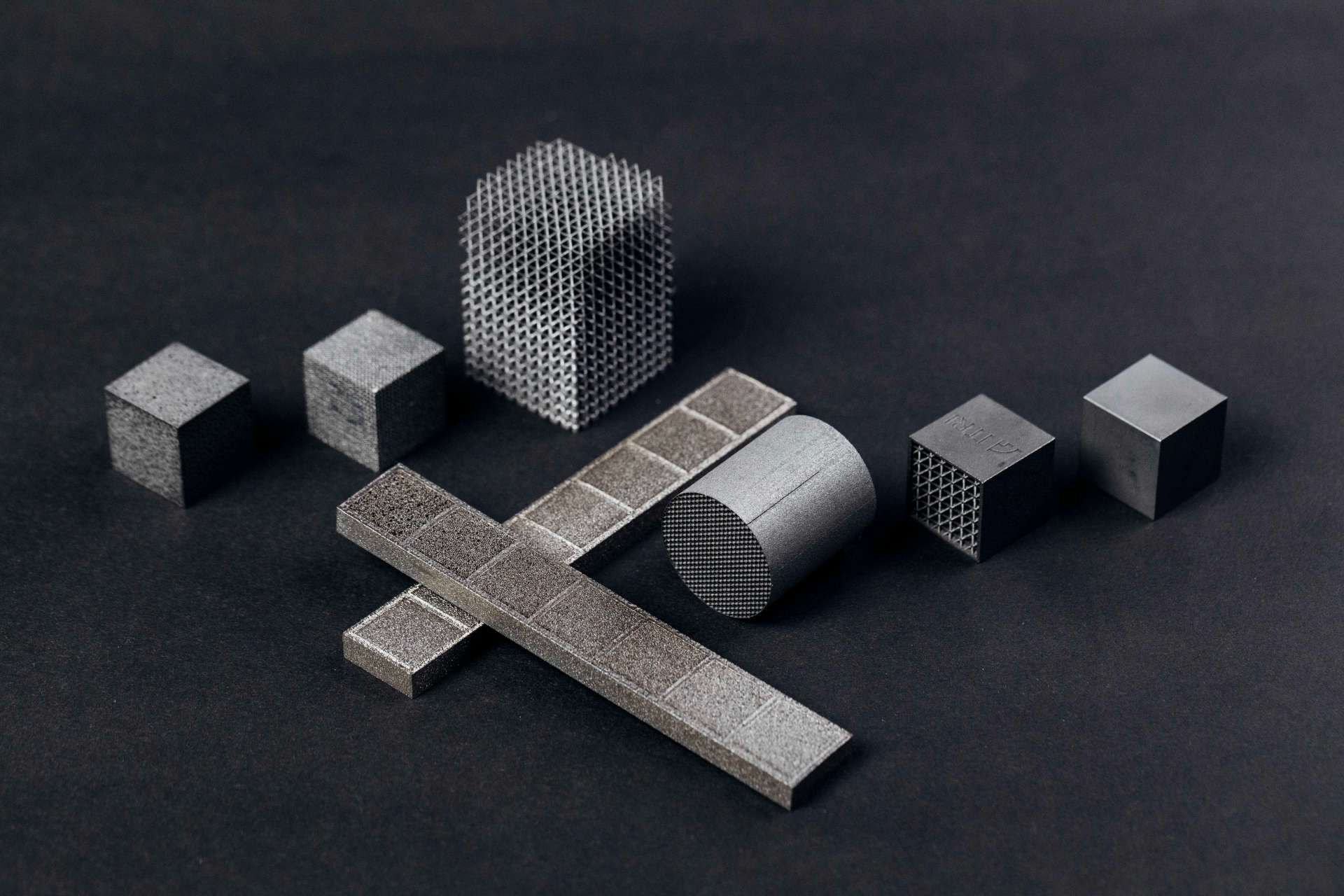

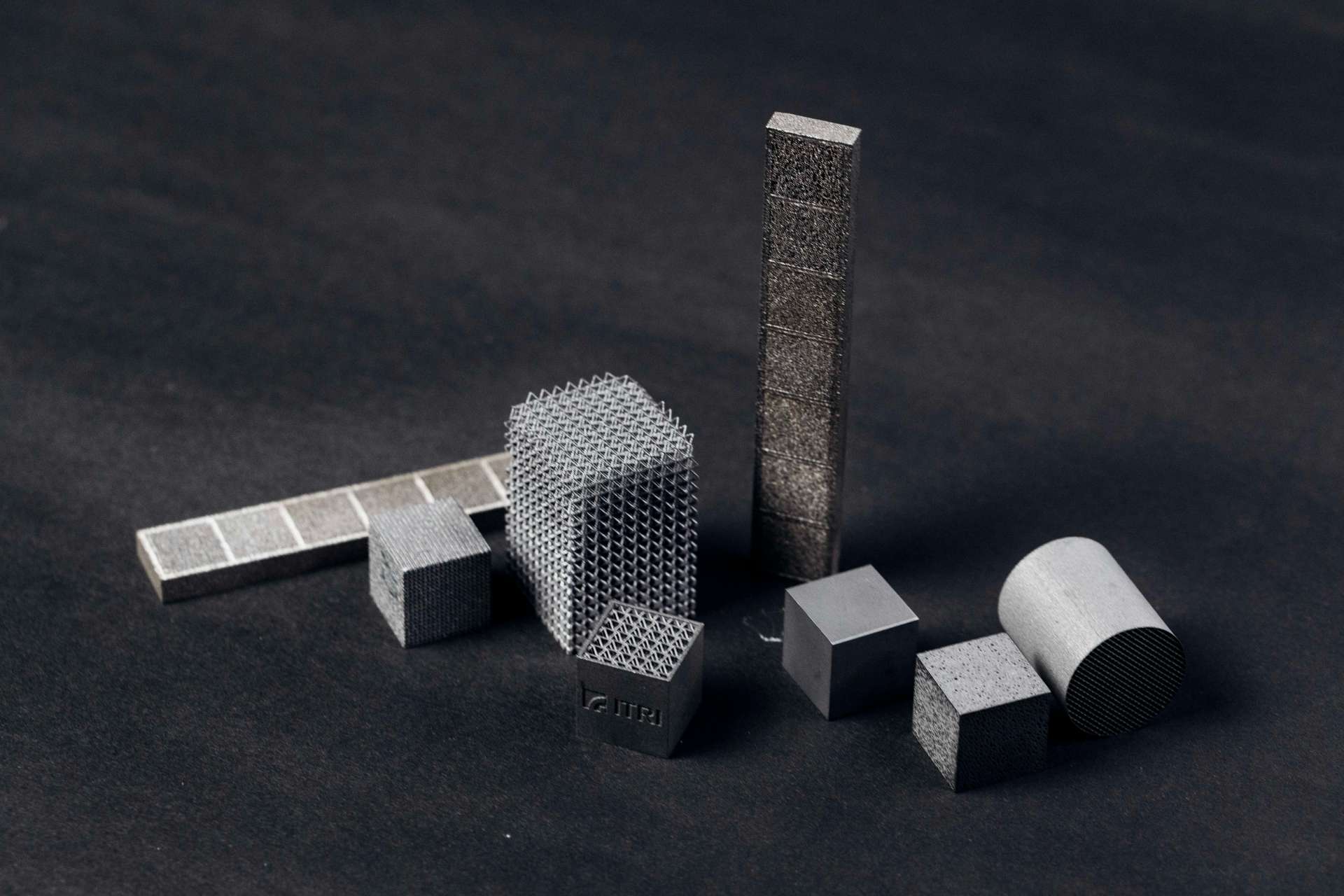

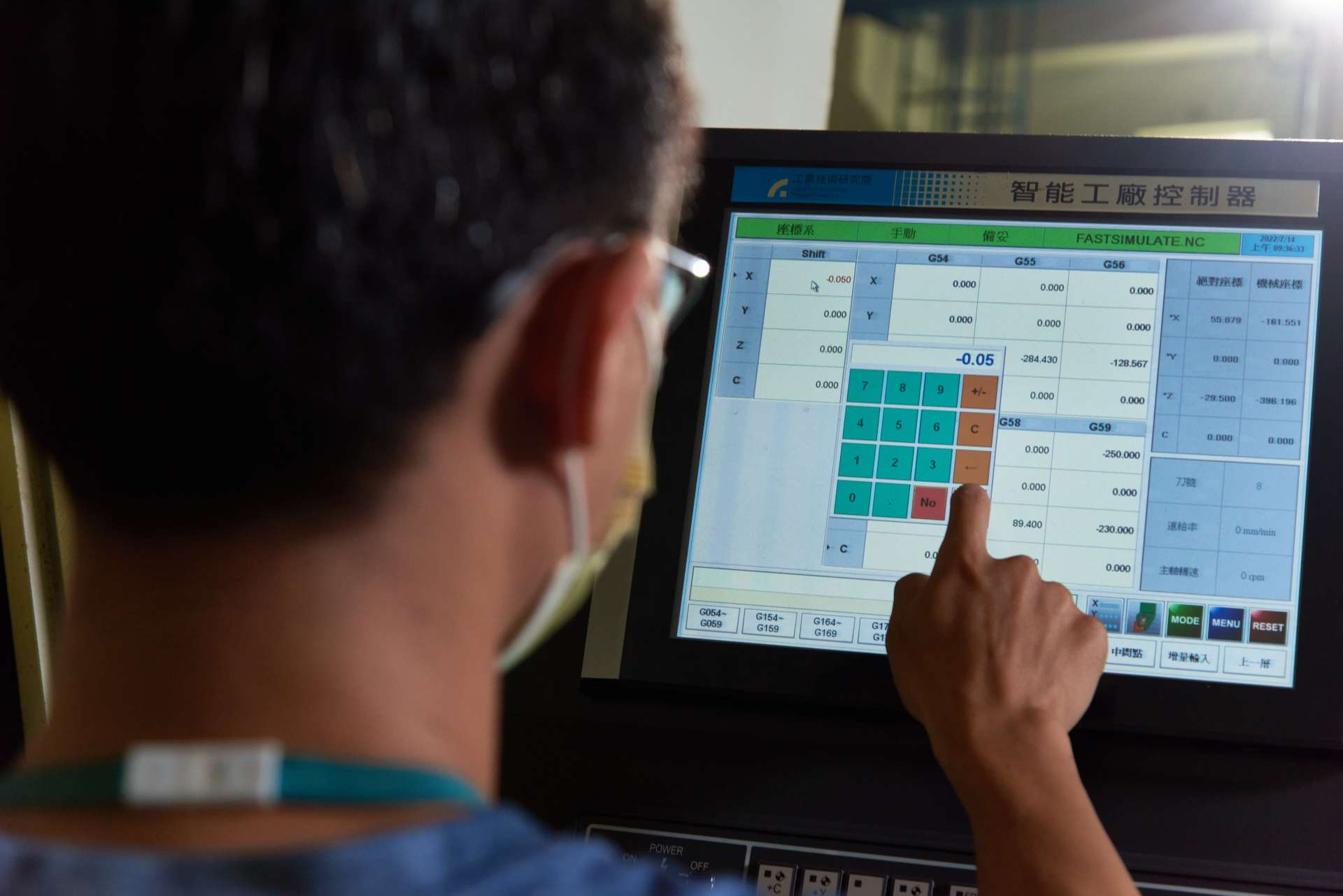

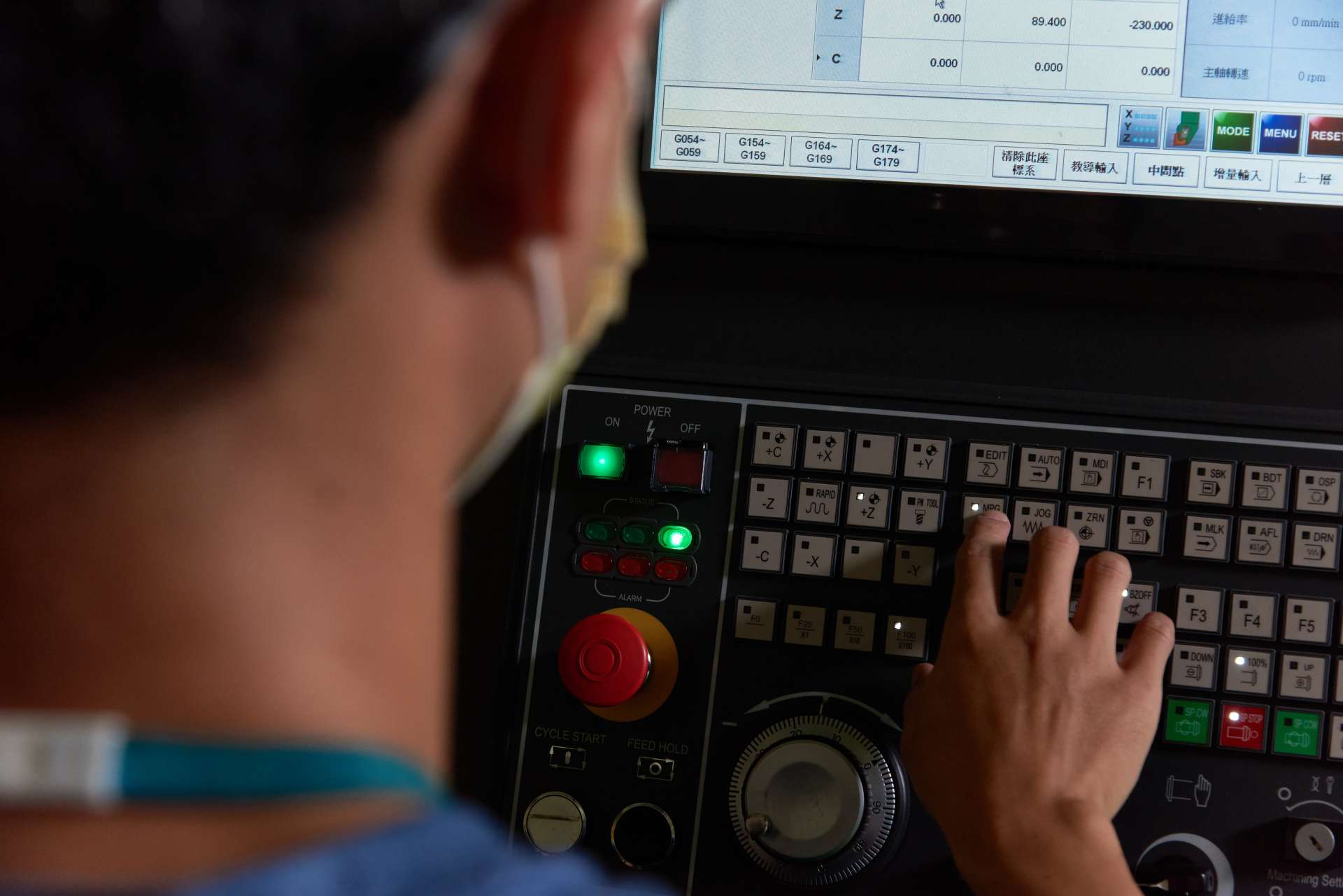

高智能化五軸加工控制器技術 High-end Intelligent Five-axis Machining Controller Technology |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

智機中心 |

| 團隊名稱 | |

| 技術 Slogan |

高精密零組件製程升級!國產高階五軸控制器 Upgrading high-precision component manufacturing with domestic high-level five-axis controllers |

| 技術簡介與應用 |

國產高階五軸加工/車銑複合控制平台,內建智慧化控制機能及加值軟體,可應用於高精密、複雜的航太、生醫及電動車等零組件加工,並將國產CNC工具機產品由單機產品提升為智慧及自動化單元解決方案,提升臺灣製造工具機自我特色與創造利潤,讓使用者好學好用好維修。 The domestic high-level five-axis machine/turning and milling control technology, with built-in smart control functions and value-adding software, can apply to high-precision, high-complexity component processing in aerospace, biomedical, and automotive industries. It transforms domestic CNC machine tools from single-machine products into smart autonomous unit solutions. It will create distinguishing features and profits for Made-in-Taiwan manufacturing machine tools that are easy to learn, use, and maintain for users. |

| 技術特點 |

・國產高階五軸控制器・智慧自動化單元解決方案・虛實控制技術整合 ・The domestic high-level five-axis controller・Smart autonomous unit solution・Cyber-Physical control technology |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

數位雙生沈浸式互動系統 Immersive Interaction System with Digital Twins |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

智機中心 |

| 團隊名稱 | |

| 技術 Slogan |

人機遠距協作−渲染3D場景技術應用服務 Human-machine remote collaboration - application and services with rendered 3D scene technology |

| 技術簡介與應用 |

後疫情時代驅動製造業對於遠端技術服務的潛在商機。以數位雙生、遠端渲染3D場景連結產線設備、操作員、技術專家協作,快速排除產線問題。 製程診斷成本、工藝轉移成本大減9成,大量客製化生產先導打樣時間縮短90%,製程效率提升30%。 The post-pandemic era created potential business opportunities for manufacturing regarding remote technical services. Utilizing digital twins and the remote rendered 3D scenes to connect production line devices, operators, and technical experts allows fast troubleshooting for the production line. The costs of process diagnostics and technology transfer can reduce by 90%. The pilot production time for massive customization can reduce by 90%, and the process efficiency can improve by 30%. |

| 技術特點 |

・人與AI雙生協作・多用戶環境監控・遠端渲染3D場景 ・Human-AI collaboration・Multi-user environment monitoring・Remote rendered 3D scenes |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

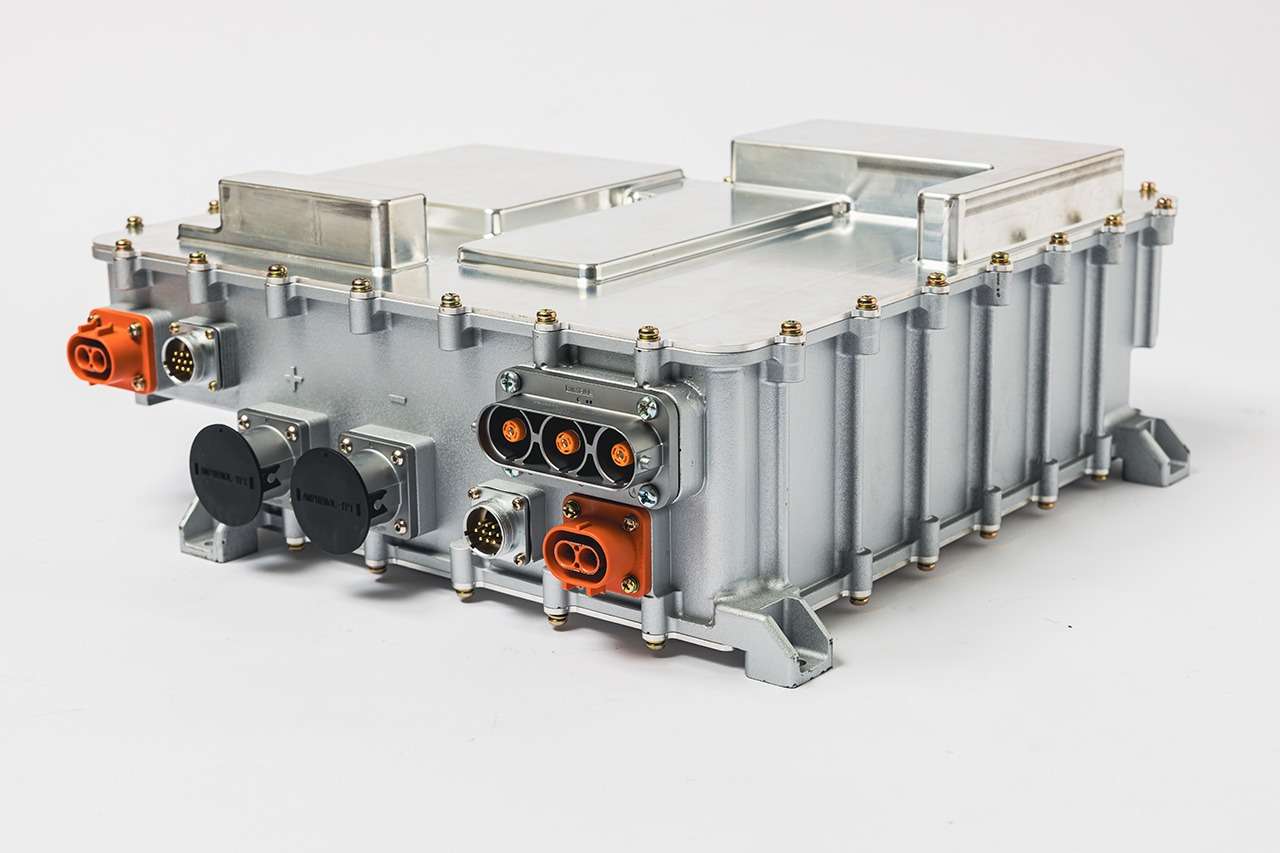

整合式電動車動力系統 Integrated Electric Vehicle Power System |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

機械所 |

| 團隊名稱 | |

| 技術 Slogan |

碳化矽SiC功率模組,打造電動車強心臟 SiC power module for stronger cores of electric vehicles |

| 技術簡介與應用 |

整合馬達、驅控器與輪軸驅動機構之模組化設計,可縮小動力系統體積與重量,提升系統功率密度,適用於3.5噸級以下之商用車型。技術採軸向端面整合機構設計,具一體式水冷散熱系統及內嵌式三相電力接合,驅控器端採用碳化矽SiC功率模組大幅提升系統性能,系統功率密度大於4.0kW/L。 This technology adopts a modular design that integrates motors, traction inverter, and axle drive mechanisms to reduce the power system's volume and weight and improve its power density. It applies to commercial vehicles of less than 3.5 tons. The technology adopts an axial end surface integration mechanism with an integrated water-cooling system and an embedded three-phase electrical power connection. The SiC power module is applied for the traction inverter to significantly improve system performance with a system power density over 4.0 kW/L. |

| 技術特點 |

・縮小動力系統體積與重量・一體式水冷・碳化矽SiC功率模組提升系統性能 ・Reduce the size and weight of the power system・Integrated water cooling system・SiC power module improves system performance |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

自主駕駛系統與自駕情境模擬技術 Self-Driving System & Scenario-Based Verification of Self-Driving Vehicle |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

機械所 |

| 團隊名稱 | |

| 技術 Slogan |

虛實整合框架進一步提昇自駕車安全驗證 The cyber-physical framework promotes further advancement in the safety verification of self-driving vehicles |

| 技術簡介與應用 |

虛實整合框架可以利用高精地圖建置的虛擬場域與混合實境車輛迴路測試提昇情境式測試的精確性。我們的技術可以有效驗證自駕車的安全性,不受時間和空間的限制。整合開源軟體也可降低開發成本。 採軟體模組設計之自主駕駛系統,已成功導入多款車種,包含電動、柴油和混合動力汽車,並於工研院、新竹市區南寮、台中水湳與日本等場域驗證,應用服務包含接駁與物流配送。 The cyber-physical framework can improve the fidelity of the scenario-based testing by utilizing the virtual environment based on the HD-map and mixed-reality vehicle-in-the-loop testing. Our technology can efficiently verify the safety of self-driving vehicles without time and space limitations. The integration of open-source software can lower the cost of development. This self-driving system that adopted a modular software design has been practically applied to various types of vehicles, including electric, diesel, and hybrid ones, and deployed in many fields, such as the Chung Hsing Campus of ITRI, Hsinchu city, Nanliao, Taichung Shuinan, and Japan. The application includes logistics and shuttle services. |

| 技術特點 |

・自駕物流系統 ・自駕車虛實整合安全驗證・混合實境車輛迴路測試 ・Self-driving system applying in the logistics system・Cyber-physical safety verification of self-driving vehicles・Mixed reality for vehicle-in-the-loop tests |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

金屬成型設備與模具回饋優化技術 Mechanical and Mechatronics Systems Research Laboratories |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

機械所 |

| 團隊名稱 | |

| 技術 Slogan |

克服機器視覺盲點,國內首創3D檢測機 Overcoming blind spots of machines- The first domestic 3D inspection device |

| 技術簡介與應用 |

國內首創3D螺旋切齒齒輪檢測機,可檢測黑皮、撞傷與崩齒等瑕疵。 組裝最佳化模組可應用於運具齒輪軸之組配,解決過去隨機選件組配造成之壓合力不足問題。支援可攜式裝置即時查看,提供跨廠區、多種機台資訊的可視化工具,增進管理效率。 The first domestic 3D helical gears inspection machine detects gear defects such as black skins, bump damages, or broken teeth. Assembly optimization module can apply in the assembly of gear shafts for carriers to avoid the lack of closing force due to the past random choice and assembly method. It also supports real-time monitoring on mobile devices and provides cross-plant, multi-machine information visualization tools to improve management efficiency. |

| 技術特點 |

・可執行複雜外型工作・快速智慧檢測・跨廠區可視化工具 ・Allow operations for complicated appearances・Fast and intelligent inspection・Cross-plant visualization tool |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

觸控式熱像測溫儀 Tablet Thermal Imaging Camera |

| 技術單位 |

國家中山科學研究院 National Chung-Shan Institute of Science and Technology |

| 隸屬部門 |

材電所 |

| 團隊名稱 | |

| 技術 Slogan |

工業/醫療兩用,高精準影像測溫 High-accuracy thermal imaging for both industrial and medical uses |

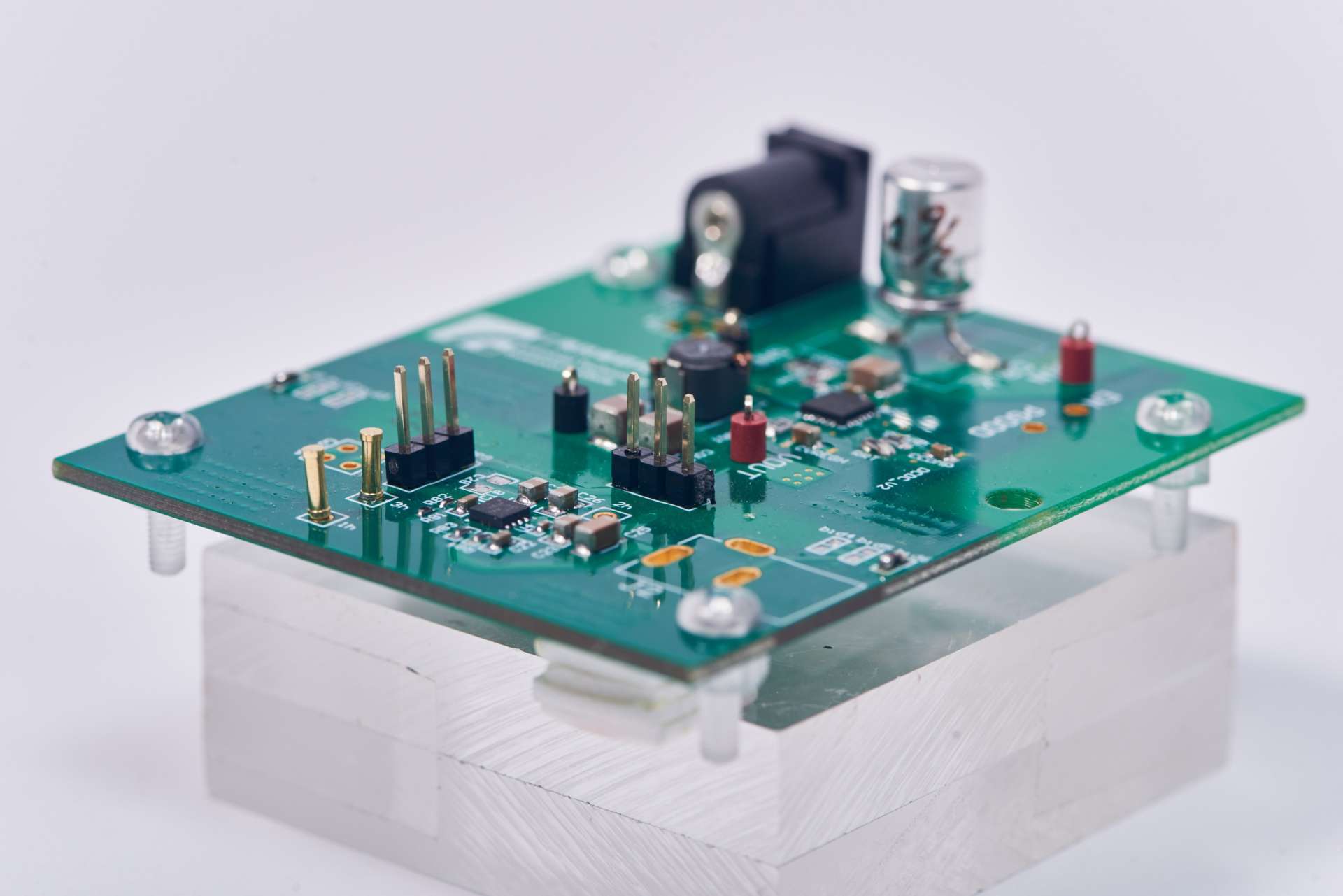

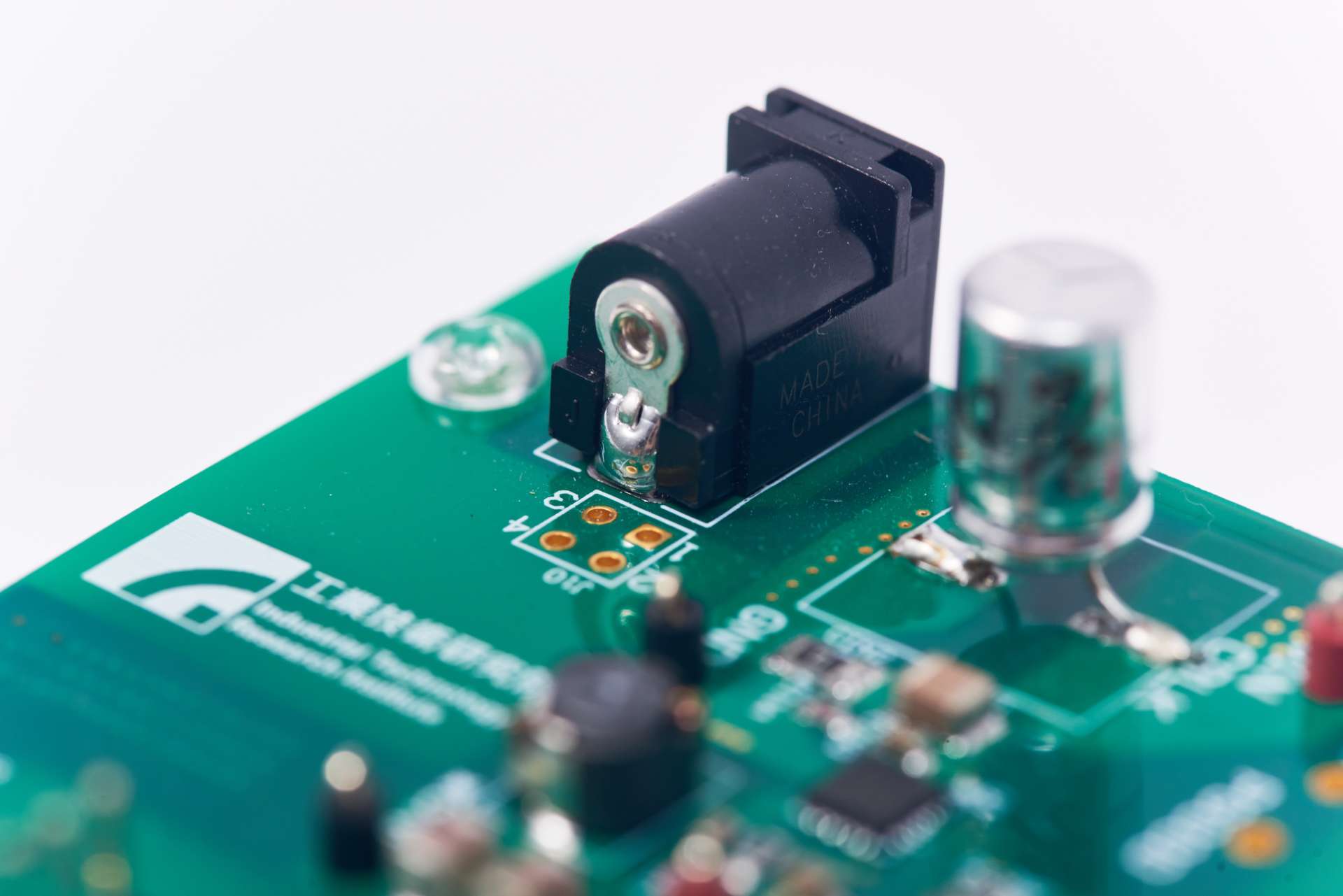

| 技術簡介與應用 |

將熱像儀整合於平板電腦,透過數位化平板介面,從資料擷取到溫度分析,以專利測溫校正提高熱影像測溫精準度。測定溫度穩定於±0.5℃以內,不僅可應用於醫療快篩中體溫量測,更可廣泛應用於工業管線及儀器熱點精密量測、山區與海上搜救作業等商用領域。 This technology implements thermal imagers to tablets and conducts everything from data acquisition to temperature analysis through the digital tablet interface. It applies the patented temperature measurement adjustment technique to improve the precision of thermography and maintains temperature measurement stability in the range of ±0.5℃. It applies in the body temperature measurement for medical rapid tests and commercial applications, such as the precision measurements for industrial pipelines or hot spots in instruments or rescue missions in the mountains or at sea. |

| 技術特點 |

・客製化數位整合介面・多功能應用場域・測溫穩定度±0.5℃ ・Customized digital integration interface・Multifunctional application areas・Temperature measurement stability ±0.5℃ |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

電動輔助登山自行車 The Key Technology Development of E-Mountain Bike |

| 技術單位 |

自行車暨健康科技工業研究發展中心 Cycling & Health Tech Industry R&D Center |

| 隸屬部門 |

--- |

| 團隊名稱 | |

| 技術 Slogan |

智慧升級電動自行車,開創產業新未來 Upgraded smart electric bike - opening a new industrial future |

| 技術簡介與應用 |

智慧電動輔助自行車系統包含整合控制邏輯技術、車架設計及通訊聯網,可根據騎乘需求客製化設計、依據騎乘模式智慧化調整動力輸出,是人們騎乘電動自行車時最佳出力輔助手。藉由三電配套系統化整合開發技術引領全球電動自行車產業發展。 The smart electric-assisted mountain bike technology integrates the control logic technology, frame design, and communication network. This product provides customized designs depending on riding needs and intelligently adjusts power output according to the riding mode. It is the best assistant for electric bike riders. The EIC matching system and the integrated development technology will facilitate the growth of the global electric bike industry. |

| 技術特點 |

・智慧電輔自行車系統・多目標車架設計優化・電輔自行車通訊聯網 ・Smart electric-assisted bicycle system・Multi-objective frame design optimization・Electric-assisted bicycle communication network |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

仿生智能AGV艦隊系統 Bionic Intelligent AGV Fleet System |

| 技術單位 |

金屬工業研究發展中心 Metal Industries Research & Development Centre |

| 隸屬部門 |

海洋科技產業創新服務處 |

| 團隊名稱 | |

| 技術 Slogan |

無人搬運車,想搬什麼都可以! Unmanned transporter for anything you want |

| 技術簡介與應用 |

技術發想源於大自然中螞蟻的搬運邏輯,結合動力輪模組以及智慧化模擬指揮系統,搭載獨立的動力設備、控制器、電池和減壓系統,形成最佳排列方式共同搬運。仿生智能AGV艦隊系統具有無線智慧、彈性運用、靈活移動的三大特色,與一般無人車相比能在各種空間中運行。 This technology originates from the ants' transportation logic in nature. It combines the mobile wheel module and intelligent simulation command system with individual power devices, controllers, batteries, and sdamping system for a converged transport with the best arrangement. The bionic intelligent AGV fleet system features wireless intelligence, flexible applications, and agile mobility to move better in various spaces compared to typical unmanned vehicles. |

| 技術特點 |

・仿生智能AGV・彈性協同作業模式・高適應性可用於各場域 ・Bionic intelligent AGV・Flexible collaboration mode・High adaptability, applies in various fields |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

智慧化3D視覺製鞋自動打粗塗膠 Intelligent 3D Visual Automation for Shoes Roughing and Cementing Equipment |

| 技術單位 |

金屬工業研究發展中心 Metal Industries Research & Development Centre |

| 隸屬部門 |

能源與精敏系統設備處 |

| 團隊名稱 | |

| 技術 Slogan |

機器人也能打磨出老師傅工藝技術 Experienced masters' crafting techniques delivered by robots |

| 技術簡介與應用 |

取代傳統人工打粗及塗膠製程,可在2秒內產生鞋面打粗塗膠之機器手臂運動路徑,更可在8秒完成一隻大底塗膠。 克服製鞋業自動化瓶頸,生產效率提升一倍,人工及耗材成本降低17% ,亦解決人工作業時吸入粉塵及有害揮發性物質等問題。 This technology replaces traditional manual roughing and cementing processes. It provides a robotic arm‘s pathway for upper roughing and cementing in two seconds and completes the outsole cementing process in 8 seconds. This technology overcomes the difficulty of automating shoe-making businesses, doubling the production efficiency, and reducing 17% of labor and consumable costs. It also prevents problems like inhaling dust and hazardous volatiles during manual operation. |

| 技術特點 |

・製鞋過程自動化 ・規劃打粗路徑,精準塗膠 ・減少人工肺傷害 ・Automation of shoemaking process ・Planning the roughing paths and applying glue accurately・Reduce lung damages from manual work |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

連續式微型元件熱處理系統設備 Continuous Micro Parts Heat Treatment System Equipment |

| 技術單位 |

金屬工業研究發展中心 Metal Industries Research & Development Centre |

| 隸屬部門 |

精微成形研發處 |

| 團隊名稱 | |

| 技術 Slogan |

2天交貨!3C元件熱處理Total Solution Delivery in 2 days! The total solution for the heat treatment of 3C components |

| 技術簡介與應用 |

全球首創針對高複雜結構或直徑2mm以下的零件,整合自動進料、即時監測與即時調控主加熱爐、創新油槽與收料裝置、智慧化服務等功能。 淬火油槽採取創新捕集機構設計,可完全捕集四散的微小零件,收料率百分百,良率達99%,交期從30天降為2天,成本大幅降低。 This product is the World's first exclusive equipment for components with highly complex structures or diameters smaller than 2mm. It integrates functions such as automatic feed, real time monitoring and carburizing quenching furnace for real-time adjustment, innovative oil tank and collecting device, intelligent digital services, etc. The oil‑quenching tank adopts an innovative capture mechanism design to gather all scattered tiny parts to achieve a 100% collecting rate and 99% yield rate. It shortens the delivery time from 30 days to two days and massively reduces the cost. |

| 技術特點 |

・連續式熱處理・全面收料・跨產業應用 ・Continuous heat treatment・Comprehensive collection・Cross-industry application |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

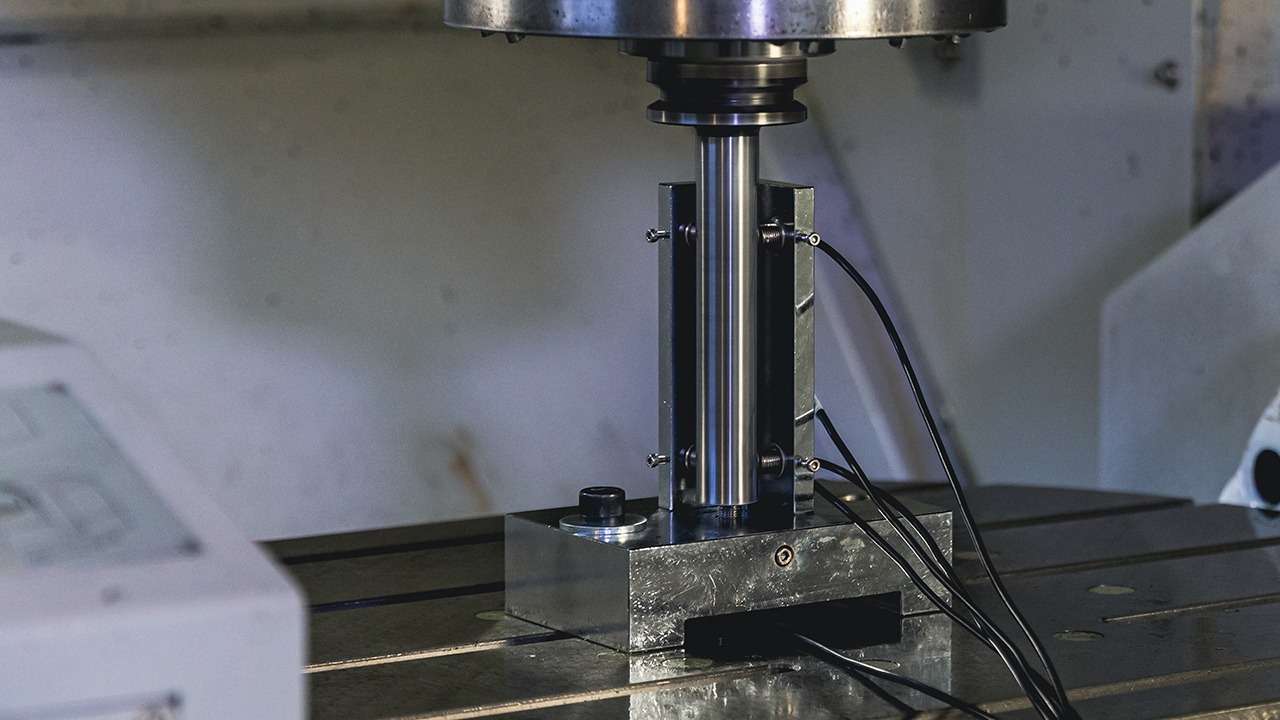

自適應熱誤差補償模組 Adaptive Thermal Error Compensation Module |

| 技術單位 |

精密機械研究發展中心 Precision Machinery Research & Development Center |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan |

打鐵趁熱,工具機加工神隊友 Strike While the Iron is Hot, Your Ultimate Partner in Precision Machining |

| 技術簡介與應用 |

針對主軸端與進給軸端首創應用AI人工智慧與大數據資料建立溫升熱補償模型,讓主軸與進給軸能自動熱補償,使精度提升80%以上;另外,以遠端通訊進行熱誤差模型修正,使熱誤差不論在何處均能控制在15µm內,並大幅降低修正工具機熱誤差的人力成本。 A groundbreaking AI and big data-driven temperature rise compensation model has been developed for the spindle and feed shaft ends, enabling automatic thermal compensation and improving accuracy by over 80%. Additionally, remote communication is used to perform thermal error model correction, ensuring that thermal errors are controlled within 15µm regardless of location, significantly reducing the labor cost associated with correcting machine tool thermal errors. |

| 技術特點 |

・可長時間維持機台熱補償精度。・確保機台加工精度與品質穩定性。・可降低工具機熱誤差的人力調控成本。 ・It can maintain thermal compensation accuracy of the machine tool over a long period of time.・It ensures stability in the machine tool's machining accuracy and quality.・It can reduce the labor cost associated with controlling machine tool thermal errors. |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

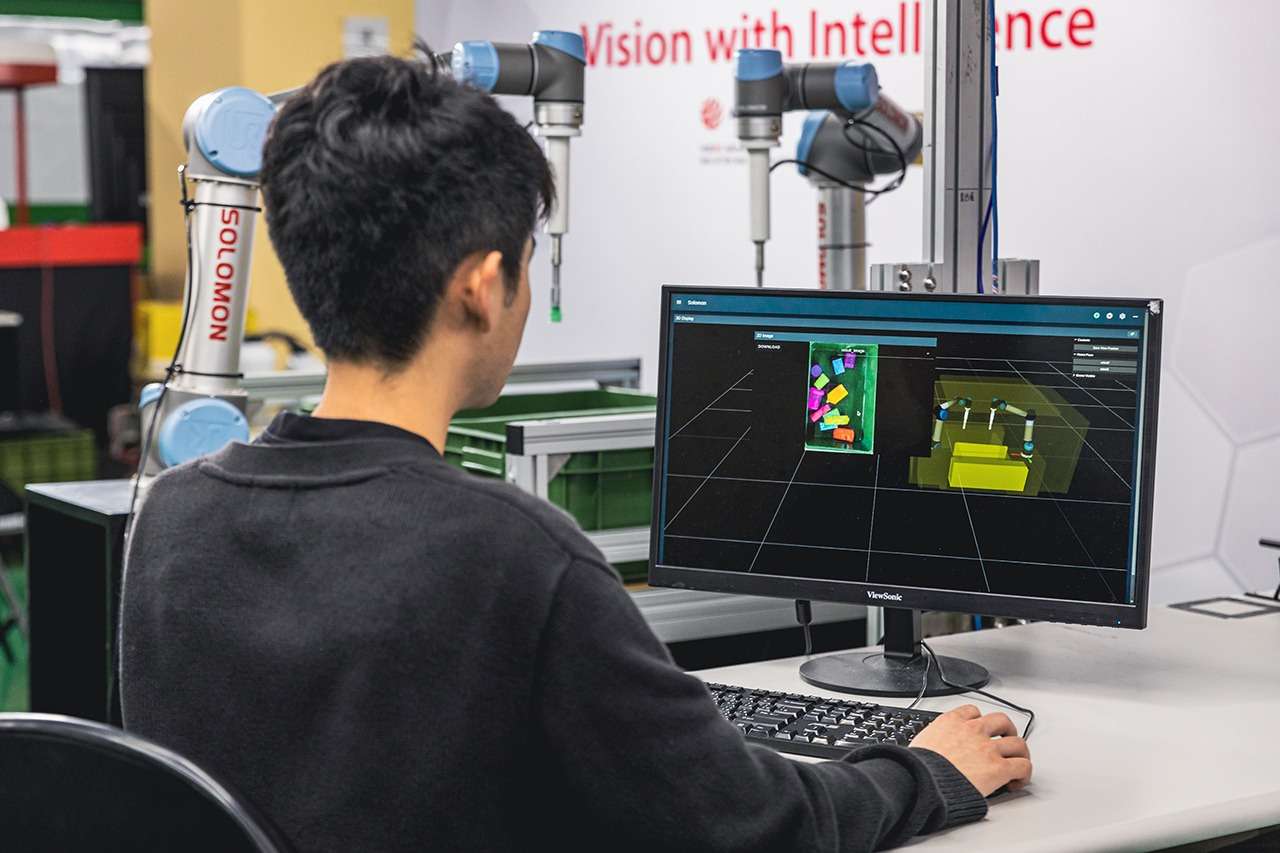

視覺智能取放系統 AccuPick |

| 技術單位 |

所羅門股份有限公司 SOLOMON Technology Corporation |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan |

機器人的最佳夥伴 實現您不可能的取放任務 Smart Bin Picking Industrial Automation Software |

| 技術簡介與應用 |

AccuPick智能取放系統僅使用少量圖像樣本就可以學習、分類物件,可辨識高度複雜圖像及傳統視覺不易辨識物件,例如金屬薄片、橡膠、紋路複雜紡織品,甚至是透明與交疊材料也可精準辨識。 AccuPick can learn and classify objects using only a small number of image samples. It can recognize highly complex images and objects that are difficult to identify with traditional vision, such as metal sheets, rubber, textiles with complex textures, and even transparent and overlapping materials. Accurate identification. |

| 技術特點 |

.與多種3D掃描器、手臂、PLC相容.自主研發AI辨識演算法.優化機器人路徑防止碰撞 .Industry Leading AI and 3D Vision.Compatible Open Platform.Collision-Free Motion Planning |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

MIT Lv4 智慧電動小巴 MIT Lv4 Intelligent Eletric Minibus |

| 技術單位 |

車輛研究測試中心 Automotive Research & Testing Center |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan |

智慧運輸,台灣未來行動力 Intelligent Transportation, Taiwan's Future Mobility |

| 技術簡介與應用 |

電動巴士整合感知定位、底盤技術、決策控制、測試驗證技術及營運監控技術形成智慧公車,適合應用於鄉鎮間短程運輸、觀光景點接駁,落實節低碳運輸兼顧經濟效益與生態永續,未來可導入偏鄉地區運行,已因應高齡化社會。 Electric buses integrate perception and positioning, chassis technology, decision-making control, testing and verification technology, and operation monitoring technology to form a smart bus, which is suitable for short-distance transportation between towns and sightseeing spots, and implements energy-saving and low-carbon transportation while taking into account economic benefits and ecological sustainability. It can be introduced into rural areas for operation, and it has already responded to an aging society. |

| 技術特點 |

1. 整合ADAS關鍵技術2. 森林遊樂區接駁運行3. 推廣國內運輸節能減碳 1. Integration of ADAS key technologies2. Connection operation of forest recreation area3. Promote energy saving and carbon reduction in domestic transportation |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

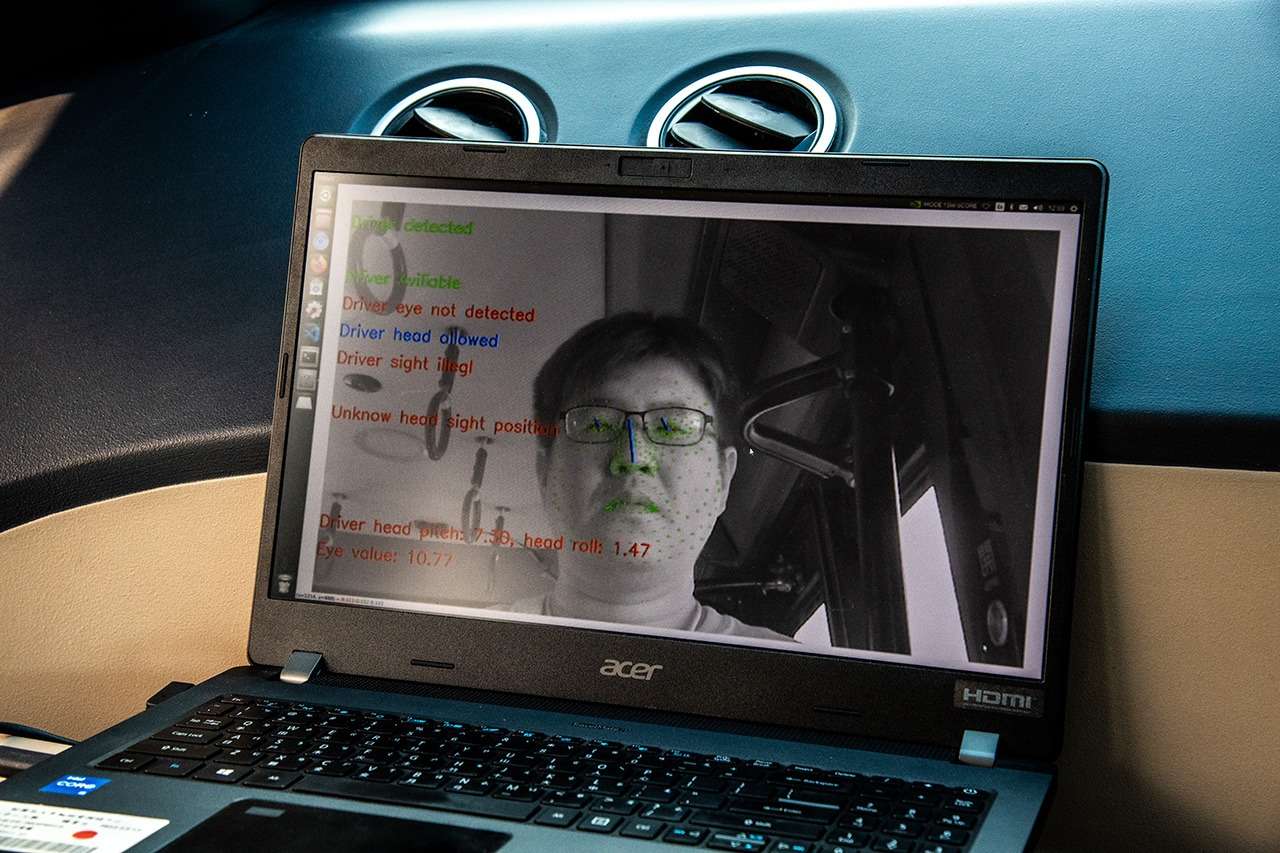

全方位智駕座艙辨識與驗證技術 All-around Intelligent Cabin with Regconize and Verify Technology |

| 技術單位 |

車輛研究測試中心 Automotive Research & Testing Center |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan |

全方位智駕座艙辨識技術,保護駕駛、乘客安全。 All-around Intelligent Cabin With Regconize Technology, making drivers and passengers safe. |

| 技術簡介與應用 |

整合「智慧化、自動化、智駕化」之「辨識與驗證」技術,透過異質感知融合技術建立AI影像辨識及生物特徵偵測,可於弱光及遮蔽中偵測孩童遺留車內,減少兒童遺留車內導致死亡。並建立駕駛人互動監控機制,對應自駕Level3整合線控底盤發展最小風險智慧決策機制。 Integrating the "identification and verification" technology of "intelligence, automation, and intelligent driving", and establish AI image recognition and biometric detection through heterogeneous perception fusion technology, which can detect children left behind in cars in low light and shading, reducing children Left inside the car resulting in death. And establish a driver interaction monitoring mechanism, corresponding to the self-driving Level3 integrated wire control chassis to develop a minimum risk intelligent decision-making mechanism. |

| 技術特點 |

1. 整合涵蓋四大創新技術2. 艙內遺留即時接收通知3. 助攻產業進軍國際市場 |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

電控煞車系統主動安全控制技術 Active Safety Control Technology of Electronically Controlled Braking System |

| 技術單位 |

車輛研究測試中心 Automotive Research & Testing Center |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan |

電控煞車系統主動安全控制技術, 讓您更安心 Active safety control technology of the electronically controlled braking system for greater peace of mind |

| 技術簡介與應用 |

電控煞車系統主動安全控制技術,包括煞車防鎖死(ABS)、電子煞車力分配(EBD)、斜坡起步輔助(HHA)等智慧煞車輔助功能,可應用於各式車輛,其煞車性能媲美國際大廠水準。 Active safety control technology of electronically controlled braking systems, including anti-lock braking (ABS), electronic brake force distribution (EBD), hill hold assist (HHA), and other intelligent brake assist functions. It can be applied to various types of vehicles and provides braking performance on par with international manufacturers. |

| 技術特點 |

1. 電控煞車系統主動安全控制技術2. 虛實操控感受煞車作動3. 自主產業鏈成形 1. Active Safety Control Technology of Electronically Controlled Braking System 2. The braking action provides a responsive and intuitive feel for real and virtual driving experiences.3. The self-developed industrial chain has been established. |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

無停轉風機無人機巡檢系統技術 Continuously Rotating Wind Turbine UAV Inspection System |

| 技術單位 |

金屬工業研究發展中心 METAL INDUSTRIES RESEARCH& DEVELOPMENT CENTRE |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan |

風機不停機情況下有效檢測運轉中的風機 This technology effectively inspects operating wind turbines without shutting them down |

| 技術簡介與應用 |

能於風機不停機情況下有效檢測運轉中的風機,5分鐘內完成單一風機檢測,有效偵測出小至 4mm的缺陷,並節省檢測成本40%以上。透過觀測運行中葉片結構與支柱整合運動狀態,能即時掌握缺陷,使運行中檢測優勢更為突出。 This technology effectively inspects operating wind turbines without shutting them down. It completes a single wind turbine inspection in 5 minutes and effectively detects defects as small as 4 mm to save more than 40% of the inspection cost. This technology detects defects in real-time by observing the blade structure during operation and the motion state of the tower, which further emphasized the advantage of inspections during operation. |

| 技術特點 |

1.7級陣風中穩定飛行2.風機不停機的情況下執行檢測模式3.5分內完成單一風機檢測 1.High-altitude stability, in winds with a Beaufort scale of 7. 2.Executing inspection of a running wind turbine. 3. Finishing an inspection of a single wind turbine in 5 minutes. |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

ROBOTSMITH CPS研磨拋光機器人3.0 ROBOTSMITH - CPS Grinding and Polishing Robot System |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

機械與機電研究所 |

| 團隊名稱 |

機器人史密斯 RobotSmith |

| 技術 Slogan |

Crafting a better future Crafting a better future |

| 技術簡介與應用 |

ROBOTSMITH以AI軟體技術克服製程瓶頸,模仿人工手法、結合EzSim應用軟體、感測技術及周邊配置實現虛實整合應用。 技術特色為:機器人編程模擬產生路徑;針對工件變異即時修正路徑;以聲音感測砂帶磨耗,AI診斷砂帶壽命;搭配上位工單系統,彈性調整視覺檢測取樣頻率等。 ROBOTSMITH overcomes process bottleneck with AI software technolgy. By imitating the skills of craftsmen, the digital software solution combines application software EzSim, sensor technology and optimal working setup to realize cyber- physical integration. The system features programming simulation of robot paths, instant correction on work path in response to incoming material, abrasion diagnosis with audio sensor and AI technology, and flexible adjustment of visual inspection frequency in accordance with work order requirements. |

| 技術特點 |

-機器人編程模擬技術-整合關鍵感測資訊,精準重現工序- AI製程參數預測與品檢 -Robot programing simulation-Critical sensor technology, precise repetition of work process-AI process parameter prediction and quality control |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

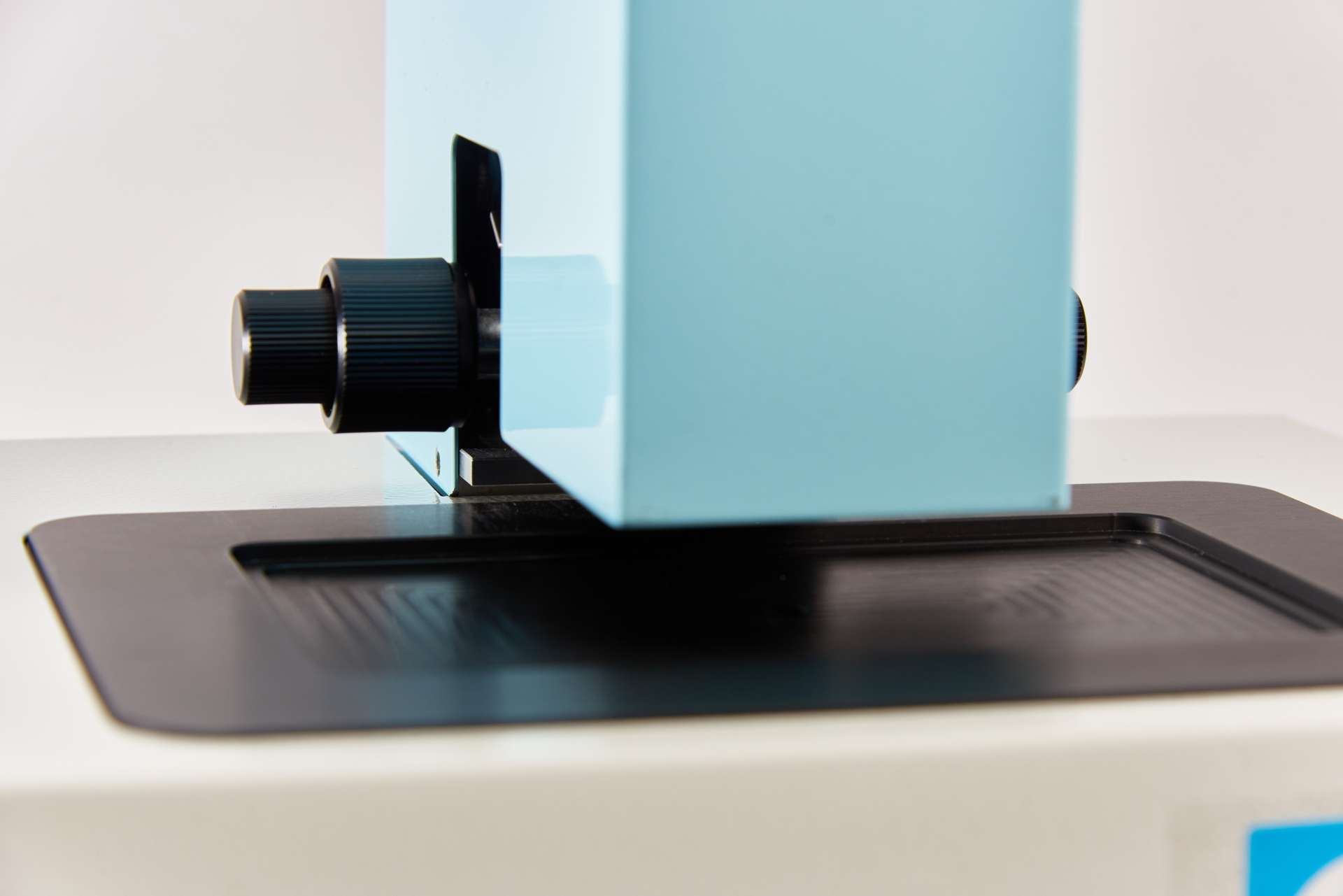

新世代奈米溶液監測系統 A Novel Monitoring System for Nano Solutions |

| 技術單位 |

兆晟奈米科技股份有限公司 Innovative Nanotech Incorporated |

| 隸屬部門 | |

| 團隊名稱 |

兆晟奈米 Innovative Nanotech |

| 技術 Slogan |

先進製程的鷹眼 Safeguard your wafer from bad wet chemicals |

| 技術簡介與應用 |

SuperSizerⓇ是唯一可以量測液體溶液裡20奈米以下的粒子和雜質的量測設備。 SuperSizerⓇ的核心技術是使用氣膠量測,可以檢測3到64奈米粒子大小及數量分布,並且不受氣泡的影響,因此量測結果具有高準確度和可信度,不僅可協助半導體製造商及供應鏈改善先進製程的良率,也可共同促進半導體產業的長遠發展。 SuperSizerⓇ is a revolutionary nanoparticle sizing system. The core technology lies in Aerosol measurement. It measures sizes and populations of nanoparticles ranging form 3nm to 64nm and is free from interference of nanobubbles. The measurement results are highly accurate and reliable. It helps to improve the yield rates of advanced semiconductor manufacturing processes. SuperSizerⓇ is the only measurement tool on the market that can detect particle sizes smaller than 20 nm and their density. |

| 技術特點 |

1. 氣膠量測液體技術2. 可檢測至3nm的雜質和粒子3. 不受氣泡影響 1. Aerosol measurement technology for liquids2. Detect impurity and particle down to 3nm3. Free from nanobubble interference |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

無人化智能手眼力機器人解決方案 Unmanned Intelligent Vision-Force Robot Solution |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

感測中心 |

| 團隊名稱 | |

| 技術 Slogan |

使智慧機器人具類人眼、類人手、類人腦的感知力與學習力 Enabling intelligent robots with human-like perception and learning capabilities similar to human eyes, hands, and brains |

| 技術簡介與應用 |

・類人眼:感測器縮小96倍,精度提升26倍 ・類人手: 多軸力感測技術,提升解析度16倍 ・類人腦: 擬真標記AI資料產生技術,訓練時間縮短32倍 ・國產手、眼、腦技術取代國外方案,推動全球首款3D AI協作機器人輸出國際,打入人機共工與庶民經濟應用 ・Human-like eyes: 3D sensors 96 times smaller, 26 times more accurate. ・Human-like hands: Multi-axis force sensing technology, 16 times higher resolution. ・Human-like brain: AI data generation with realistic labeling, 32 times faster training. ・Domestic innovation replacing foreign solutions, developed the world's first 3D AI Co-bot for global export and industrial and domestic applications. |

| 技術特點 |

・高精準微型3D感測器・精微薄型可多軸力感測 ・自動產生不同產品取物點 ・High-precision miniature 3D sensor・Ultra-thin form factor with multi-axis force sensing capability・Automatic generation of picking points for different products |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

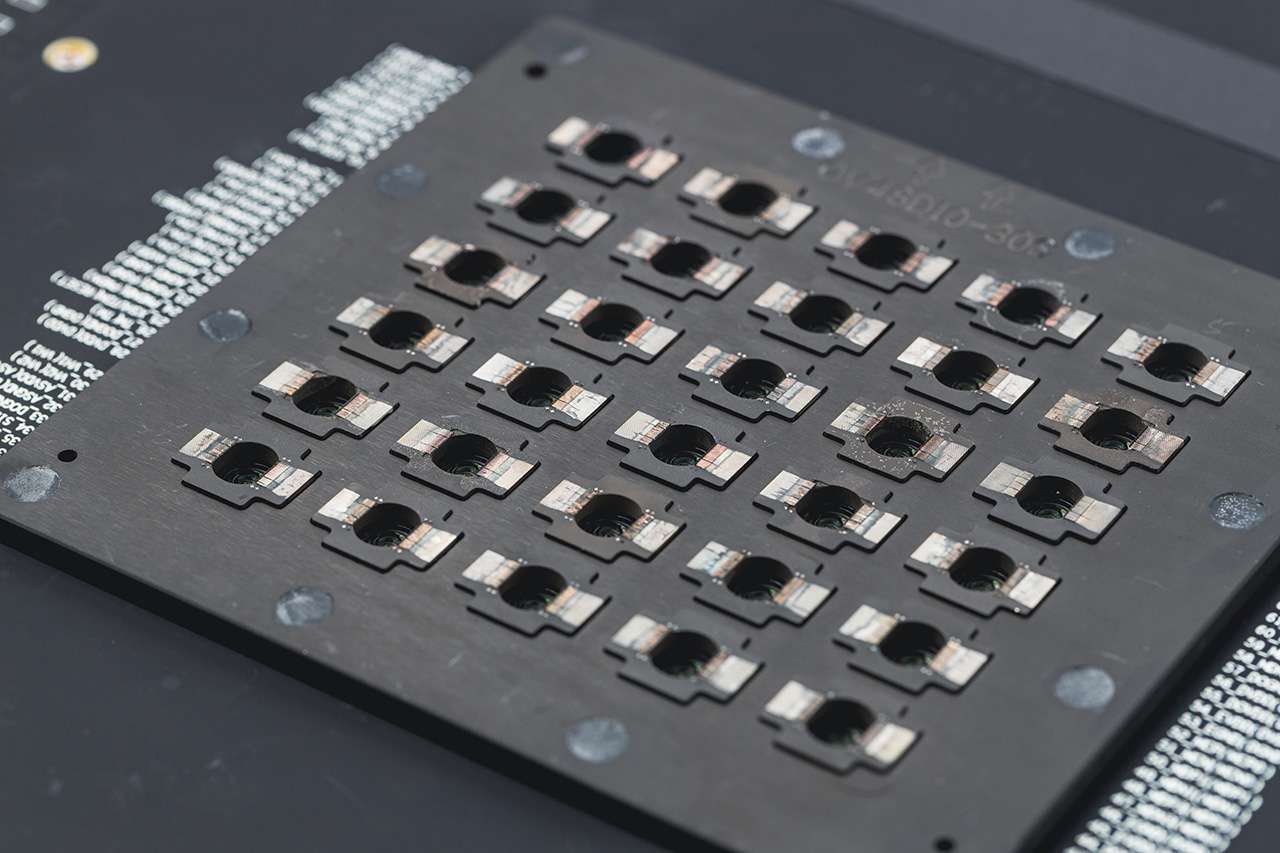

| 技術名稱 |

高強度高密度探針卡 High-strength and High-density Probe Card Technology |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

機械所 |

| 團隊名稱 | |

| 技術 Slogan |

極微細、模組化、免裝針,滿足晶圓測試的未來需求 Ultra-fine, Modularized, Free of manual needle installation,Meeting the Future Demands of Wafer Test |

| 技術簡介與應用 |

傳統探針卡之金屬探針強度低且較長,不利於製作極微細探針及高頻測試,且全靠人工裝針。高強度高密度探針卡技術創新開發「高強度微懸臂探針模組」以及「3D陶瓷電路板」:可製作針徑<20 µm的極微細探針;免人工逐針組裝;可滿足高頻測試需求(>6 GHz)。 The metal probes of the traditional probe card are low in strength and long, which is not conducive to the production of ultra-fine probes and high-frequency testing, and probes are assembled manually. High-strength and high-density probe card technology, innovative development of "high-strength micro-cantilever probe module" and "3D ceramic circuit board": can make ultra-fine probes with a needle diameter of <20 µm; free from manual needle-by-pin assembly; can meet High frequency test requirements (>6 GHz). |

| 技術特點 |

1.可製作針徑<20 µm的極微細探針;2.模組化探針免人工逐針組裝;3.可滿足高頻測試需求(>6 GHz)。 1. It can make extremely fine probes with a needle diameter of <20 µm;2. Modular probes are free from manual assembly needle by needle;3. It can meet the high-frequency test requirements (>6 GHz). |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

自駕車系統安全設計驗證與即時診斷 Verification and Diagnosis System for Self-driving Vehicle Safety |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

機械所 |

| 團隊名稱 | |

| 技術 Slogan |

自駕車的安全夥伴 Safety Co-Pilot for Autonomous Vehicle |

| 技術簡介與應用 |

虛實整合情境測試與即時診斷安全監控提供自駕系統從開發到運行的安全解決方案。混合實境測試100%重現情境,零碰撞風險,得到自駕車真實反應。自駕系統即時自動偵測軟硬體錯誤,取代人為離線分析,若有異常,立即啟動安全處理程序,達到自駕等級 Level 4。 Cyber-physical scenario-based testing and real-time diagnostic safety monitoring ensure the safety of autonomous vehicles. Mixed-reality scenario testing allows for a 100% reproduction of scenarios without collision risks, enabling true responses from autonomous vehicles. The system detects errors in real-time, eliminating the need for offline human analysis. The safety handling process is immediately activated if the system detects abnormalities, reaching Level 4 autonomy. |

| 技術特點 |

・虛實整合情境 100% 重現・即時軟硬體監控・Level 4 安全處理程序 Rapid deployment of cyber-physical scenario-based testingReal-time software and hardware monitoringLevel 4 safety handling process |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

RoboTwin 元宇宙智慧工廠 RoboTwin MetaFactory |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

機械所 |

| 團隊名稱 | |

| 技術 Slogan |

超前模擬:透過高擬真度的模擬器技術,事前規劃工廠產線佈建,降低導入失敗風險及成本。 Advanced Simulation: Through high-fidelity simulator technology, pre-planning factory production line layout to reduce the risks and costs of implementation failures. |

| 技術簡介與應用 |

RoboTwin元宇宙智慧工廠平台有別於數位雙生系統,除虛實整合外,更具備人的模擬功能。可透過VR裝置創造使用者沈浸感與真實感。本技術已與國際電機大廠合作,針對可生產電動用動力模組的馬達產線,透過RoboTwin平台技術串連AI與智慧製程,建立客戶專屬的元宇宙廠模擬系統,超前模擬與線上即時掌握產線狀態,降低不必要的成本與提升生產效率。 RoboTwin's Metaverse Smart Factory platform offers more than a traditional digital twin system, with the added ability to simulate human interactions and create a sense of immersion through the use of VR. Developed in collaboration with international electrical manufacturers, the platform enables advanced simulation and real-time monitoring of production lines, reducing costs and improving efficiency through AI and intelligent processes. |

| 技術特點 |

高擬真渲染技術:提供高真實度的外觀表現。 高擬真物理推算技術:提供高真實度動靜態的模擬。 虛實融合技術:串連虛擬與真實世界雙向訊號,進行回授控制與參數分析優化等。 提供沈浸式體驗,與虛擬端工廠進行互動。 High-fidelity rendering technology: Provides realistic visual appearance.High-fidelity physics-based simulation technology: Provides realistic dynamic and static simulation.Hybrid technology: Connects virtual and physical worlds through signal feedback for feedback control and parameter analysis optimization.Immersive interaction: Provides an immersive experience through interactive engagement with the virtual factory. |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

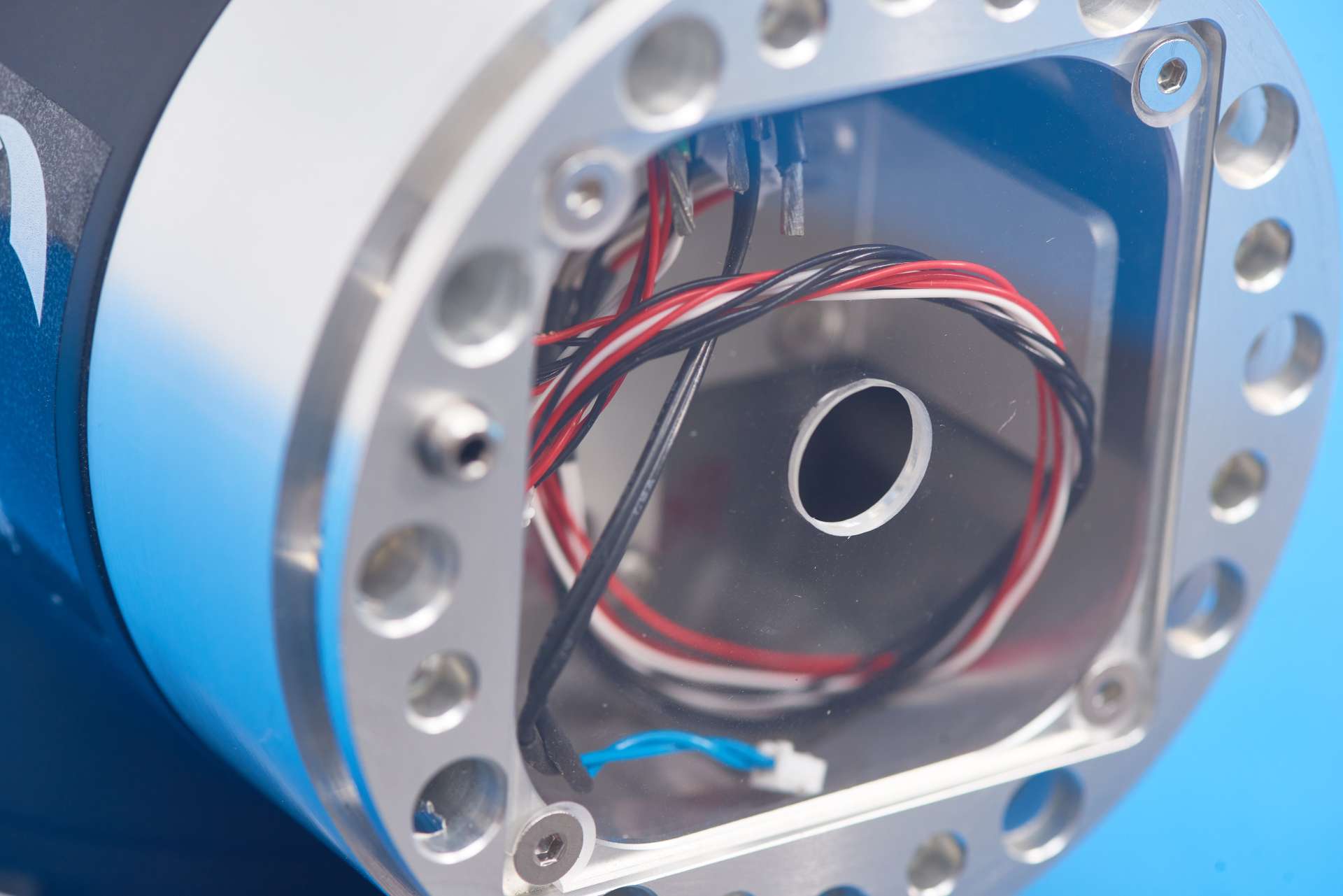

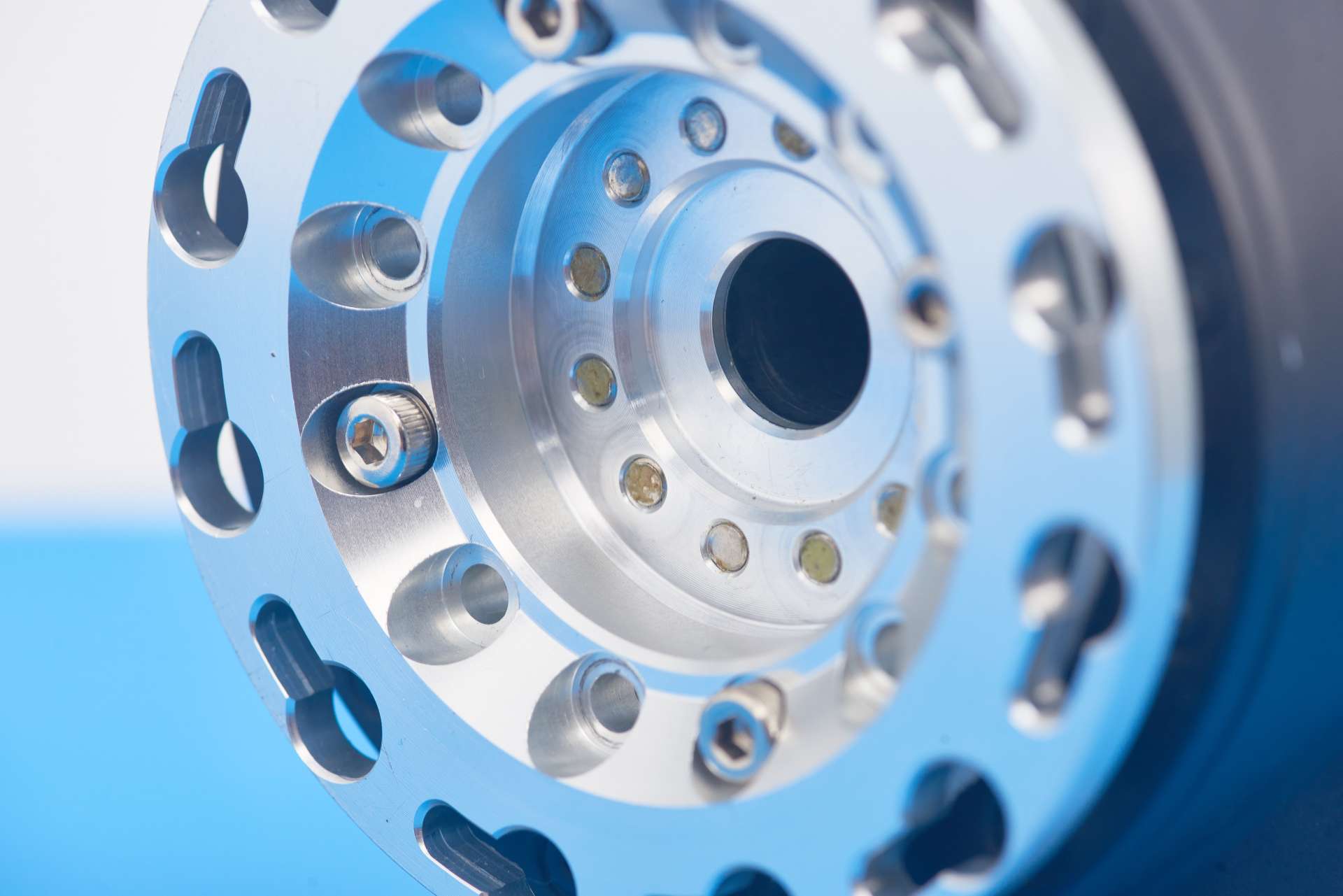

| 技術名稱 |

高功率輪邊電動後軸設計技術 High Power Wheel Motor in Rear Axle |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

機械所 |

| 團隊名稱 | |

| 技術 Slogan |

提升動力系統性能,整車應用地形更廣泛 Improving the performance of the power system allows the vehicle to be applied in a wider range of terrains. |

| 技術簡介與應用 |

永磁無刷內轉子馬達結合雙階行星齒輪傳動模組,建立高承載與小體積之輪邊電機模組,與國際指標產品相比,功率密度提升20%,提升整車性能。此外,為了提升馬達散熱能力,開發高導熱且具流動特性之馬達封裝材料,可提升散熱速度21.3%,此技術也可導入半導體產業。 The permanent magnet brushless inner rotor motor combined with the dual-stage planetary gear transmission module establishes a high power density module. Compared with international index products, the power density is increased by 20%. In addition, in order to improve the heat dissipation capacity of the motor, the motor packaging material with high thermal conductivity and flow characteristics can be developed, which can increase the heat dissipation rate by 21.3%. |

| 技術特點 |

・全車低底盤架構・動力模組化,提升共用性・首創高導熱馬達塗膠 ・Full Low-floor Chassis Architecture.・Modular Powertrain, Enhancing Interchangeability.・Pioneering High Thermal Conductive Motor Coating |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

高功率碳化矽驅控器暨多模式車用電源轉換器 High Power Density SiC Inverter and Multi-mode Automotive Power Converter |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

機械所 |

| 團隊名稱 | |

| 技術 Slogan |

超高功率碳化矽驅控器 多模式高功率車載充電器 Ultra high power density SiC inverter Multi-mode high power on-board charger |

| 技術簡介與應用 |

1.開發高功率密度碳化矽驅控器,提供更節能的方案,可解決電動車續航力及充電速度等問題。 2.採用碳化矽功率模組,並開發一體化驅控板,可縮小體積及降低成本。1. 採用整合水冷架構,導入碳化隙SiC元件,優化散熱系統提升功率密度。2. 採用雙向充放電拓樸,未來可結合運用至V2X (e.g. V2H、V2G)應用。 1. Development of high power density SiC inverter, providing more energy-saving solutions, which can solve the problems of battery life and charging speed of electric vehicles. 2. The core technology is the use of SiC power modules and the development of integrated drive control boards, which can reduce volume and cost. 1. Adopt integrated water-cooling structure, and use SiC power transistors to optimize the cooling system and increase power density.2. Adopt bi-directional charging and discharging topology for the V2X (e.g. vehicle-to-home(V2H), vehicle-to-grid(V2G)) applications in the future. |

| 技術特點 |

50kW/L高功率密度低升數驅控器體積設計整合碳化矽功率模組 二合一水冷架構 雙向充放電拓樸 軟切換控制策略 50kW/L high power density Small size inverter volume designIntegrated silicon carbide power module Integrated water-cooling architecture Bidirectional charging and discharging topology Soft switching control strategy |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

騎乘運動科學應用:E-Bike室內智能騎乘系統 An Application of Cycling Science: Indoor E-Bike Smart Cycling System |

| 技術單位 |

自行車暨健康科技工業研究發展中心 Cycling & Health Tech Industry R&D Center |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

本技術將電動輔助自行車轉換為室內訓練器材,整合電輔車原有感測元件作為運動狀態感測用途,並應用於實施室內訓練。另外,本技術可以藉由騎乘數據估計個人運動能力,同時取得虛擬教練的指導參數,,在訓練過程中提供指導訊息,藉此提升個人化精準運動之成效。 This technology converts electric-assisted bicycles into indoor training equipments, integrates the sensing elements of e-bikes for exercise state sensing, and applies them to indoor trainings. In addition, this technology estimates individual's ability through riding data, and at the same time obtain the guidance parameters of the virtual coach, and provide guidance information during the training process, thereby improving the effect of personalized and precise sports. |

| 技術特點 |

電輔車數據擷取與傳輸兼容室內騎乘互動應用即時個人虛擬教練指導 Electric vehicle data acquisition and transmissionCompatible with indoor riding interactive applicationsInstant Personal Virtual Coaching Instructions |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

5G AIoT智慧製造服務(設計-製造-後勤) 5G AIoT Smart Manufacturing Service (design-manufacturing-logistics) |

| 技術單位 |

金屬工業研究發展中心 Metal Industries Research & Development Centre |

| 隸屬部門 |

金屬中心 |

| 團隊名稱 | |

| 技術 Slogan |

切入成品設計、設備調校、設備維修,提供扣件完整智慧製造解決方案 Provide a complete smart manufacturing solution for fasteners |

| 技術簡介與應用 |

面對扣件缺工及人才斷層問題,切入成品設計、設備機台調校、 SOP排解跟維修有關的問題,利用協同回饋修正設計 ; 同時協助模具快速調模 ; 最後透過AR遠端維修指引。未來以整體解決方案輸出,解決產業人力資源不足問題且推動數位轉型。 Faced with the problem of lack of labor and talent gaps in fasteners, we cut into finished product design, equipment machine adjustment, and SOP to solve problems related to maintenance, and used collaborative feedback to revise the design; at the same time, we assisted in the rapid mold adjustment of the mold; and finally through the AR remote maintenance guidance. In the future, it will output an overall solution to solve the problem of insufficient human resources in the industry and promote digital transformation. |

| 技術特點 |

設計:提供模具最佳設計建議製造:提供模具AR調整指引後勤:設備AR遠距維修指引 Design: Provide advice on the best design of the moldManufacturing: Provide mold AR adjustment guidelinesLogistics: Equipment AR Remote Maintenance Guidelines |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

半導體矽穿孔線上檢測技術 In-line Semiconductor Through-Silicon Via Inspection Technology |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

量測中心 |

| 團隊名稱 |

超能檢測特攻隊 OmniMeasure |

| 技術 Slogan |

提供快狠準3D IC晶片封裝檢測方案的專家 OmniMeasure gives you the fastest and most accurate 3D IC chip packaging inspection solutions |

| 技術簡介與應用 |

由於高精密低功耗及工藝複雜性高的3D晶片需求量俱增,並要求更高算力,驅動高深寬比的 3D IC 矽穿孔(Through Silicon Via, TSV)封裝技術成為下世代封裝主流,現有光學量測設備已無法滿足高深寬比的3D 晶片量測。 OmniMeasure運用專利化非破壞式光學檢測方法,實現高深寬比的3D IC 矽穿孔封裝技術之深度檢測能力,在兼顧快速準確下能大幅提升矽穿孔製造良率,以因應先進封裝廠商對高速運算晶片之品質檢測的需求,目前已和國際大型半導體製造廠商進行研發合作。 3D IC technology with high precision, low power and high complexity satisfies the emerging demands for increased computing power. Therefore, 3D IC through silicon via (TSV) packaging technology with high aspect ratio has become the mainstream of next-generation packaging. Available optical measurement equipment can no longer meet the measurement of 3D IC with high aspect ratio. OmniMeasure uses a patented non-destructive optical inspection method to achieve fast and accurate depth inspection of high aspect ratio 3D IC through silicon via. It could improve yield of advanced packaging to meet the needs of high performance computing. OmniMeasure has research and development collaboration program with world leading semiconductor manufacturers. |

| 技術特點 |

1.產品提供了一種非接觸式、非破壞性和高速光學檢測解決方案2.能檢測高達 60 的深寬比之TSV 深度3.幫助半導體製造商比以往更快地發現 TSV 缺陷,提高HPC 和 AI 應用的 3D-IC 的良率 1.Noncontact, nondestructive, high-speed optical inspection solution2.Monitoring the TSV depth with high aspect ratio up to 603.Early detection of TSV defects to enhance yield rate of 3D-IC for HPC and AI applications |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

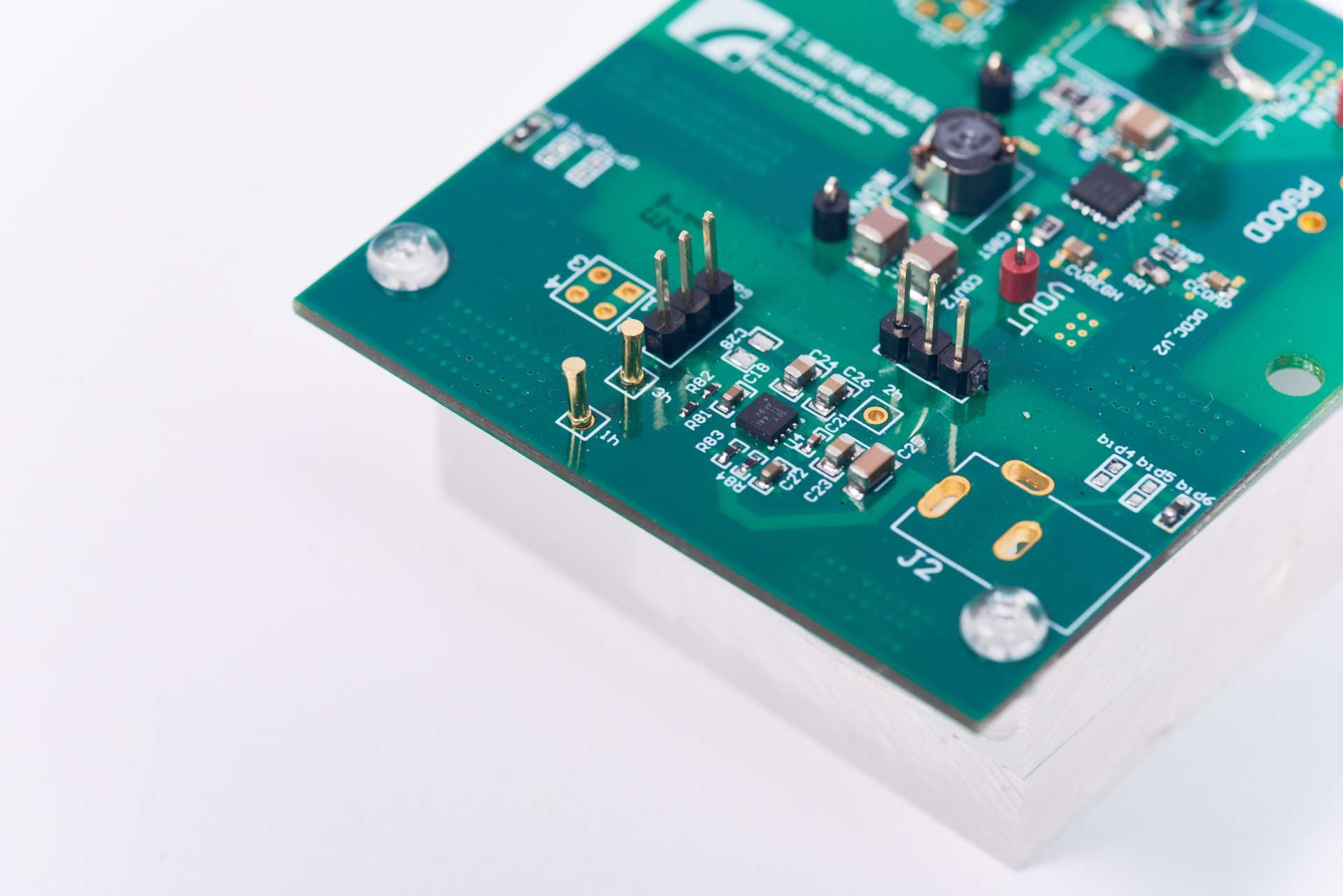

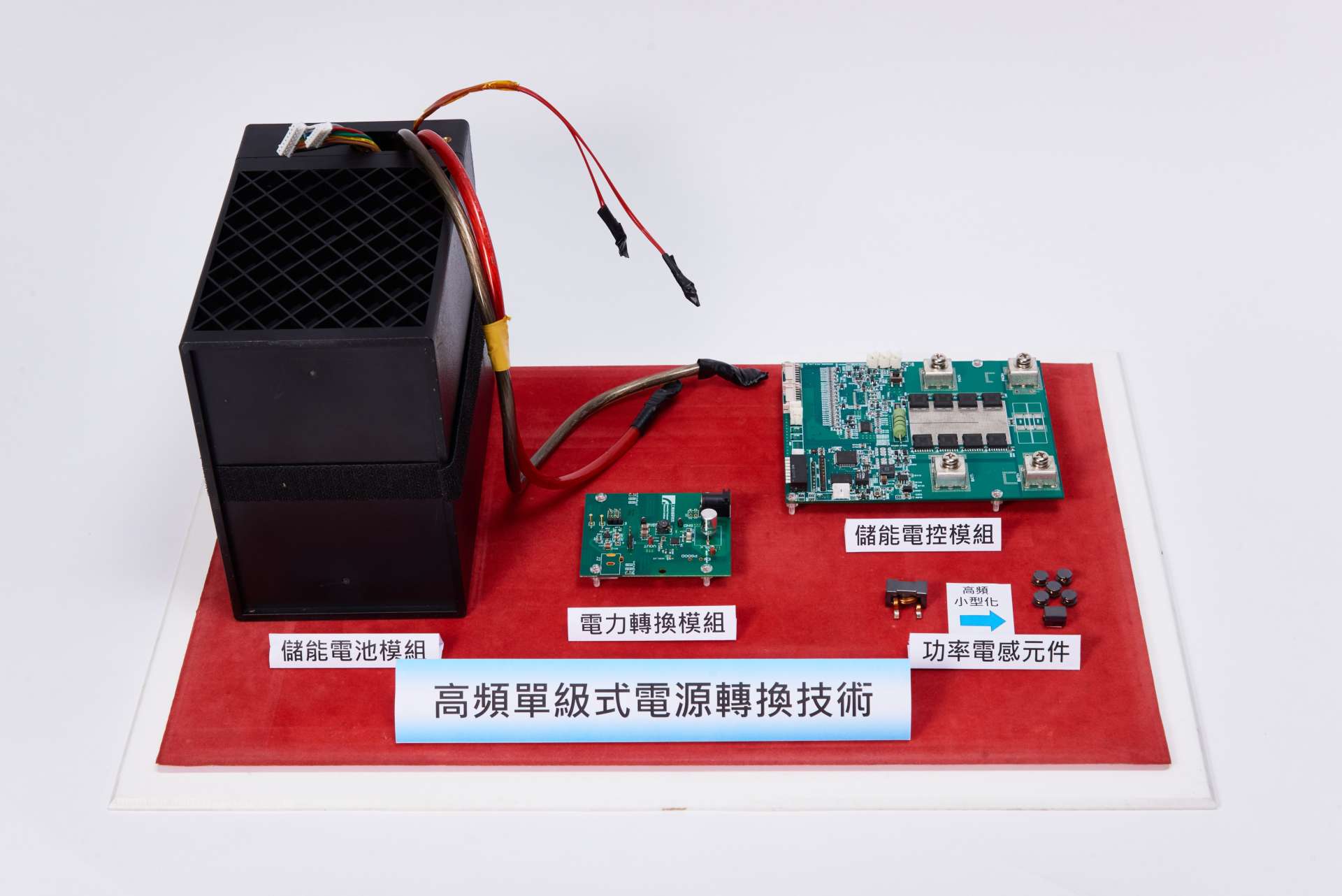

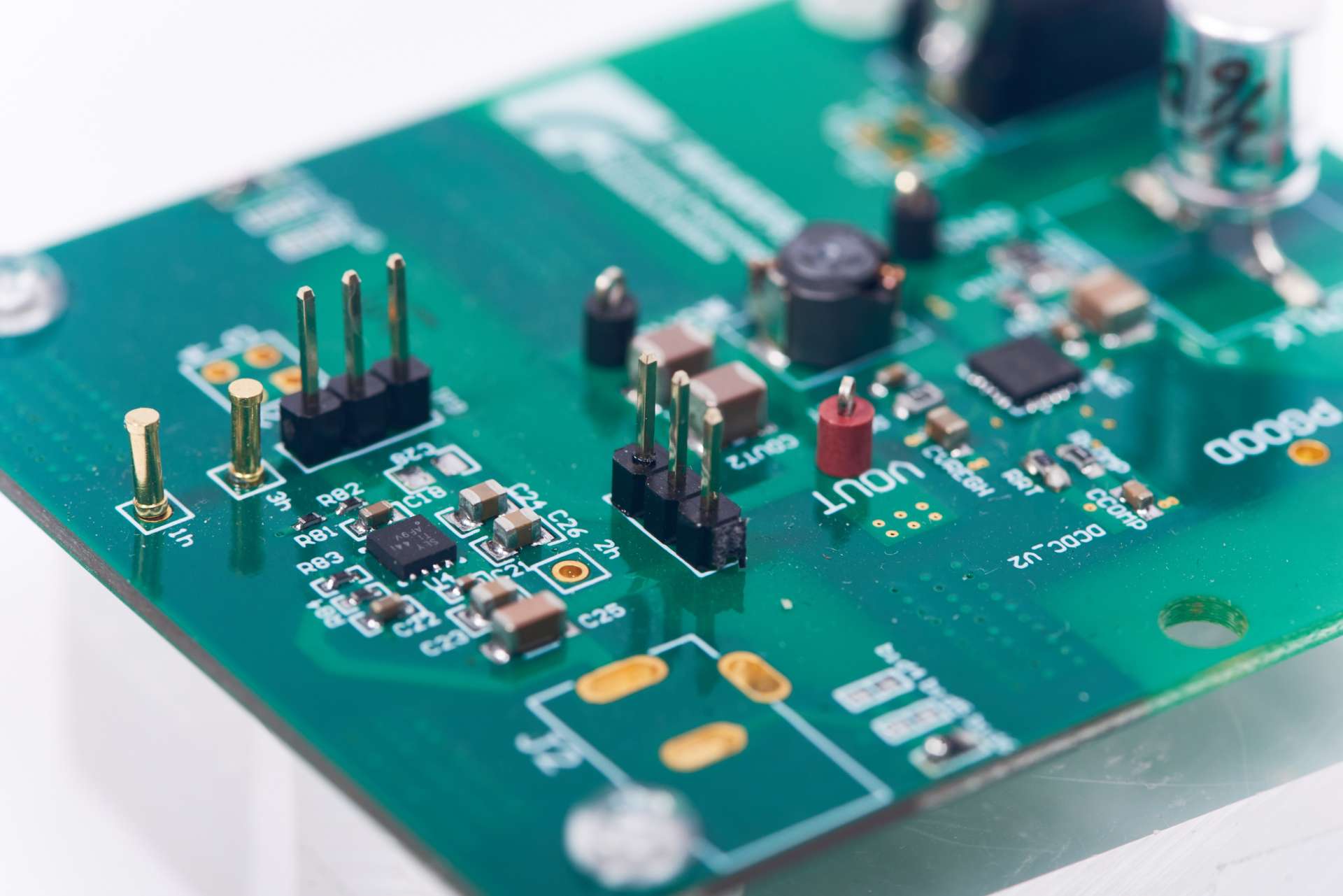

| 技術名稱 |

高頻單級式電源轉換技術 High Frequency Single Stage Power Conversion Technology |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

材化所 |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

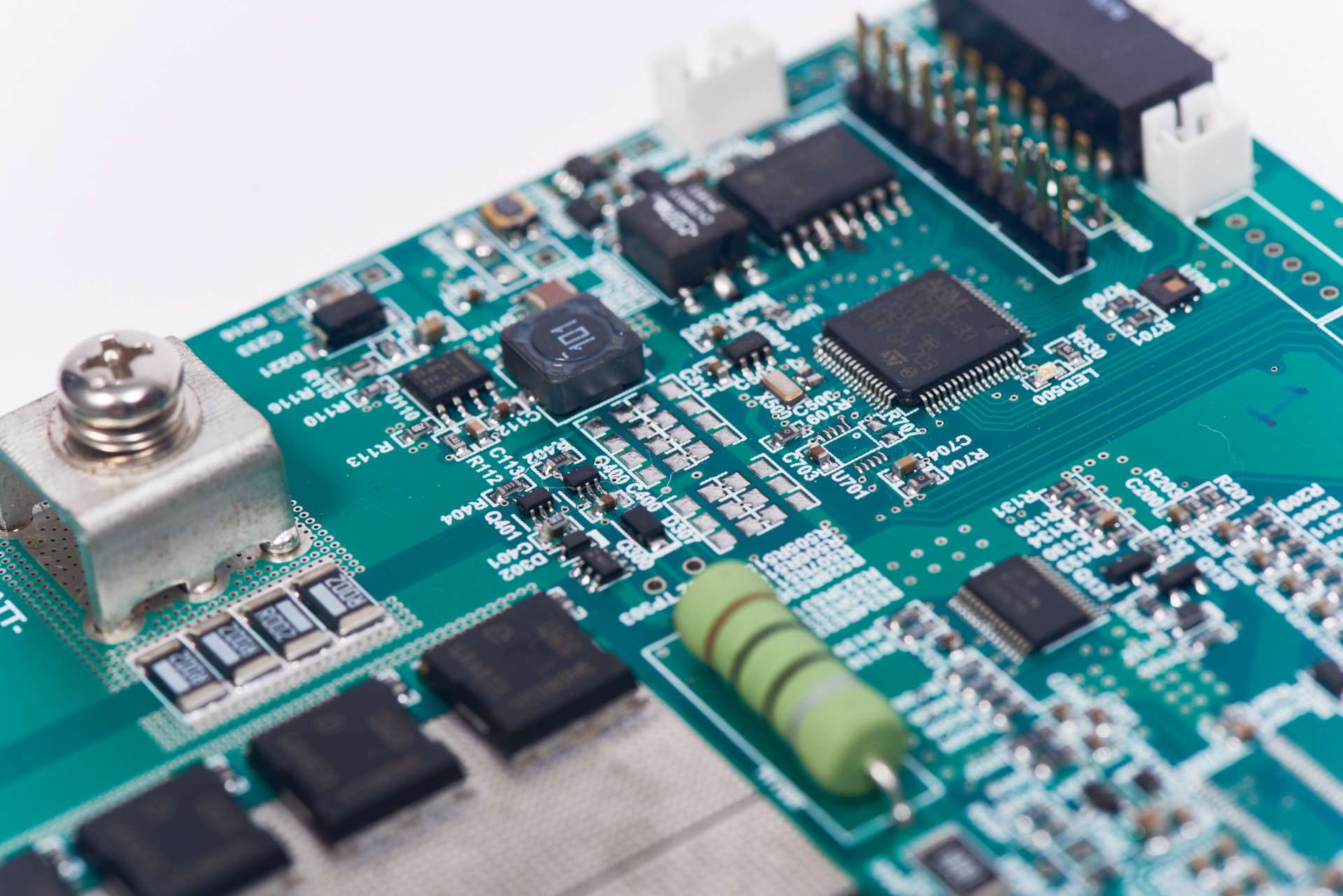

單級式電源轉換技術可最小化電源晶片使用數量成本及縮減50%元件佔板面積,高頻化能選用較小的被動元件,進一步降低佔板面積。應用至儲能電控模組,可實現應用裝置小型化及系統簡約化,最終提升終端應用的儲能效能與降低儲能成本。 The single-stage power conversion technology can minimize the cost and the number of power chips and reduce the board area of the components by 50%. The high frequency can use smaller passive components to further reduce the board area. Applied to the energy storage electronic control module, it can realize the miniaturization of the application device and the simplification of the system, and finally improve the energy storage efficiency and reduce the energy storage cost. |

| 技術特點 |

• 應用裝置小型化• 電源佔板面積縮減50%• 提升儲能效能、降低成本 • Single-stage type reduces component number• Reduction in board area by 50%• Reduced component size with high frequency |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

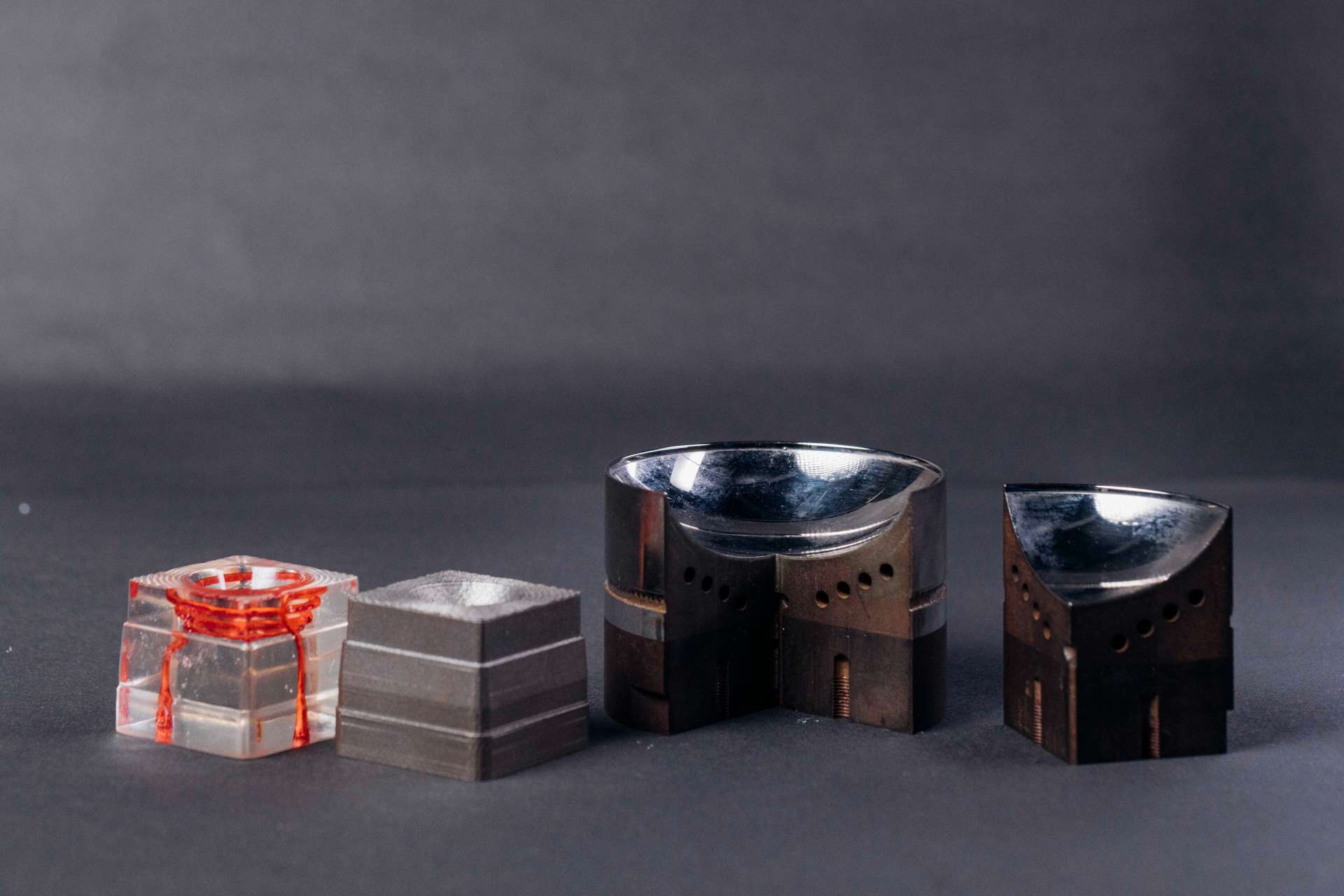

| 技術名稱 |

鋁合金積層製造模具應用 Additive Manufacturing of Aluminum Parts and Applications |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

南分院 |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

(1)數位製造轉型 (2)智慧積層製造與減碳節能 (3)創新製造 (1)Digital manufacturing transformation (2)Intelligent additive manufacturing and carbon reduction and save energy (3)Innovation manufacturing |

| 技術特點 |

設計與製造無界限突破傳統製造無法加工的極限 Design and manufacturing without boundariesAbility to create shapes that are difficult or impossible for traditional method |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

工具機跨平台虛擬切削檢視平台技術 Cross-Platform Virtual CNC Machining Technology |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

智機中心 |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

跨平台虛擬切削檢視模組技術,以3D快速切削模擬,檢測加工過程是否發生碰撞,並進行工時估算,精準協助製造排程規劃。工具機業者可輕易建構虛擬切削模型,提供客戶軟體加值服務,提升高階機台的產品競爭力。 Cross-Platform Virtual CNC Machining Technology provides 3D high speed machining simulation to detect the interference of machining process and evaluate machining time for assistant of manufacturing scheduling.CNC maker can provide value-added software service to increasing the competitive of products through easily constructing model of customized machine. |

| 技術特點 |

・快速切削模擬・ISO刀具及汎用刀座・跨平台實機參數切削 ・High speed CNC machining simulation・ISO tool and universal tool holder database・Cross platform virtual machining with real machine parameters |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

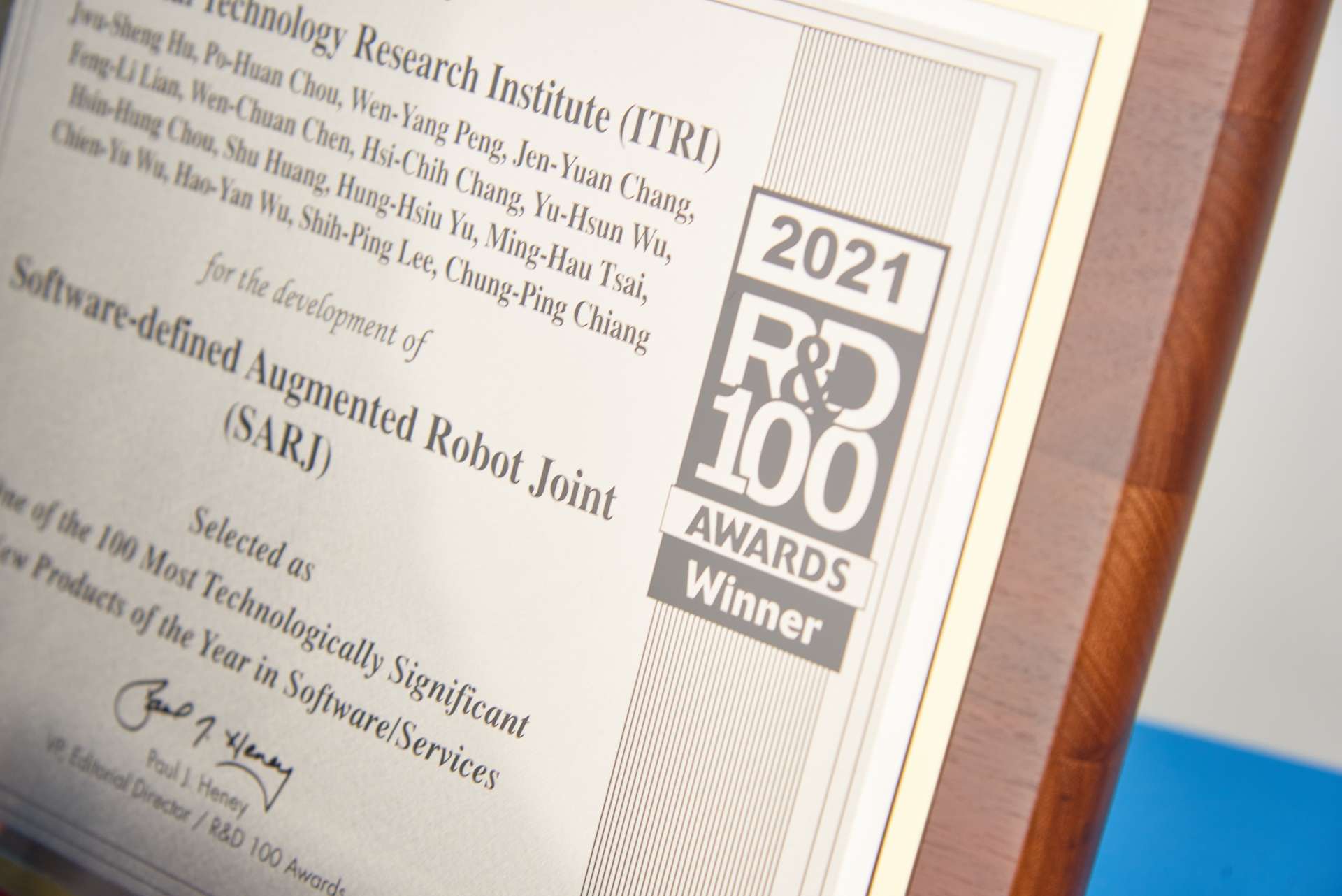

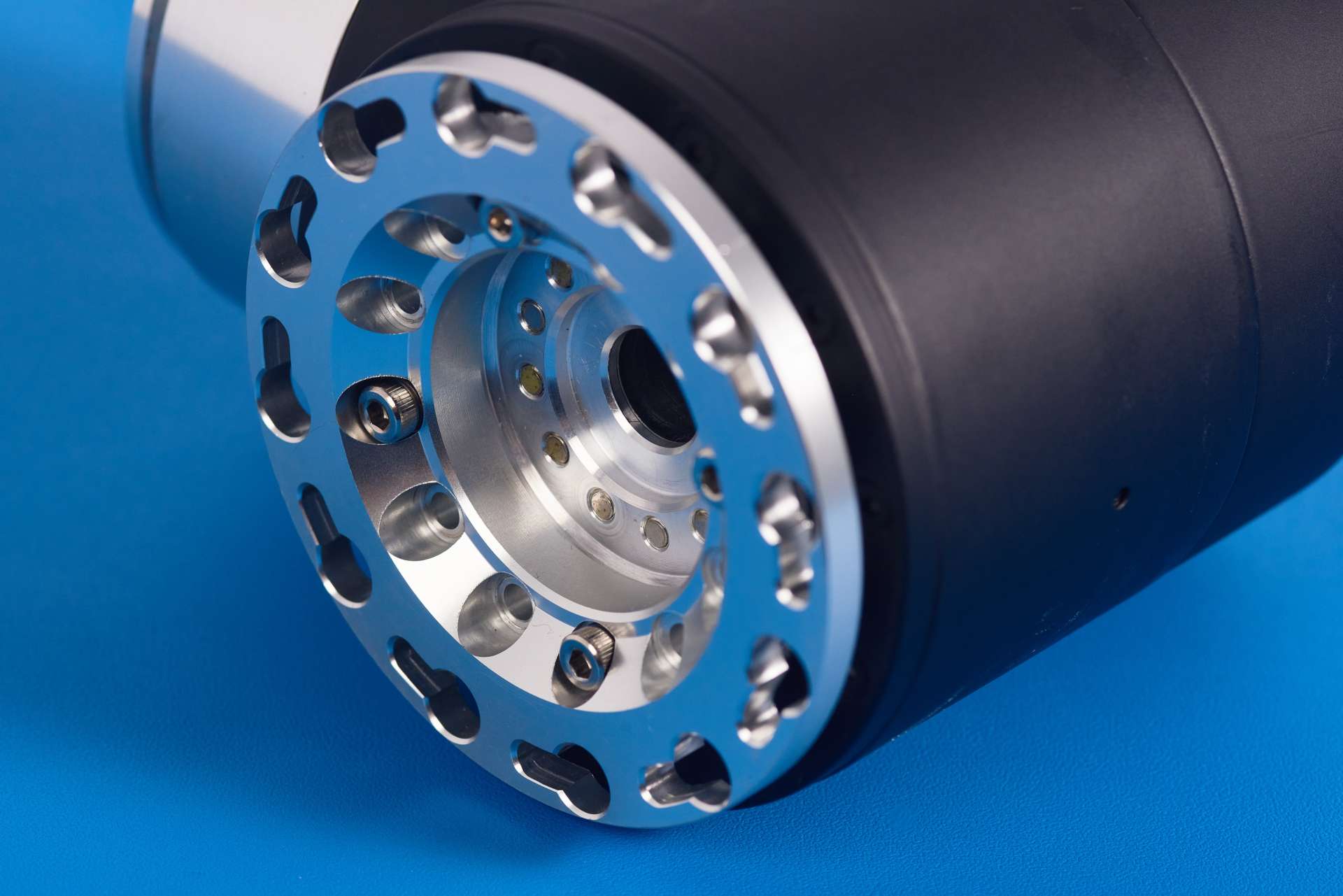

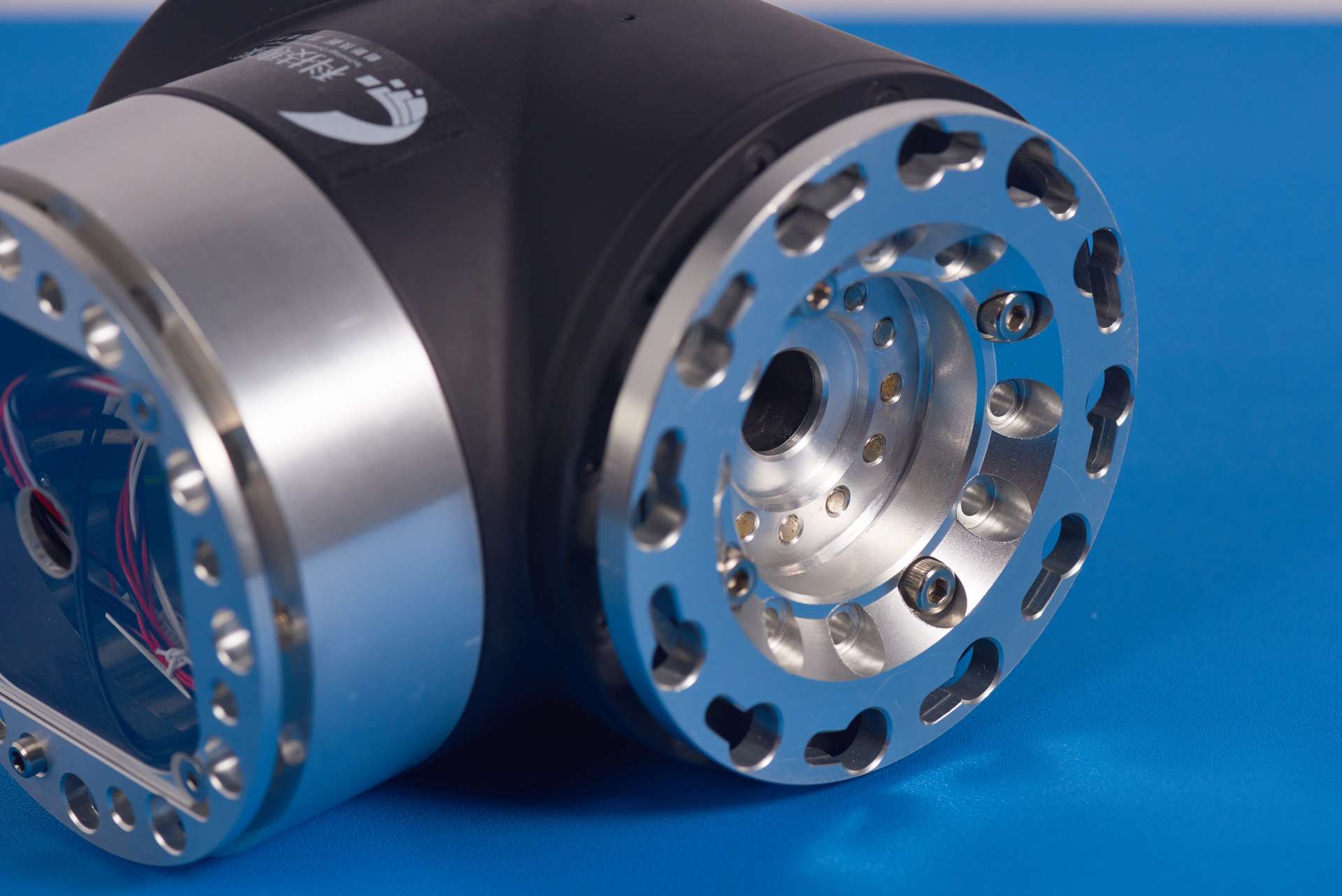

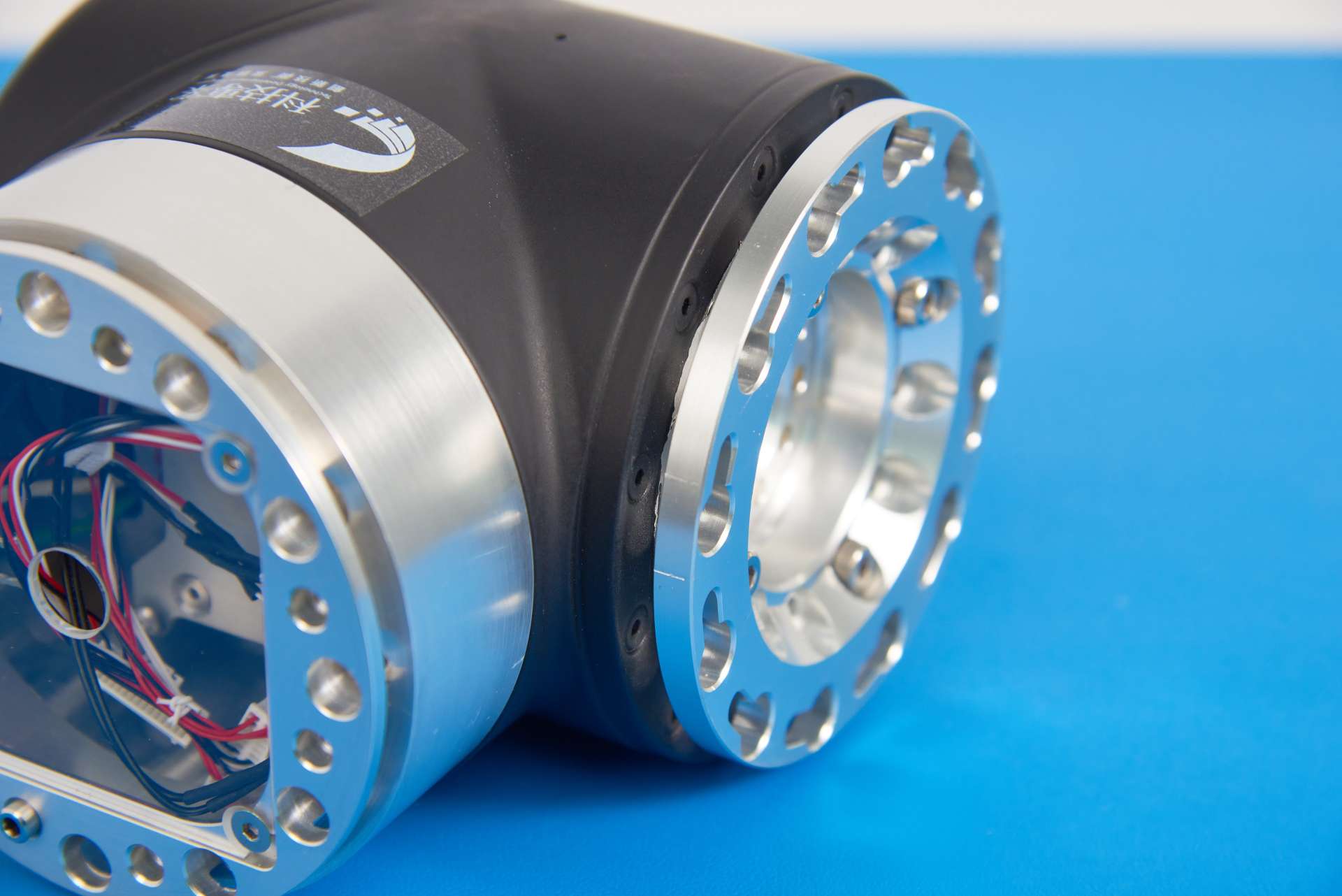

| 技術名稱 |

軟體增強型機器人關節模組(SARJ) Software Augmented Robot Joint |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

機械所 |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

本技術的機械手臂關節模組解決過去設備不夠輕巧、元件整合性不高的問題。透過一體式伺服整合馬達、驅動器、位置碼器等機電模組,電機優化設計使馬達功率體積比提升22%,無感測器的力感測技術達到省配線、省空間的目標,整體有輕量化結構與電機控制上的整合設計。 The mechanical arm joint module solves the problems that the equipment was not lightweight and the integration not high in the past. The servo joint integrates electromechanical modules such as motors, drivers, and position encoders. The optimized design of the motor increases the power-to-volume ratio of the motor by 22%. The sensorless force sensing technology achieves the goal of saving wiring and space. |

| 技術特點 |

・高功率密度機電模組設計・無感測器之力感測技術・馬達與驅動器智慧整合 ・High power density・Sensor-free technology for force sensing・Intelligent integration of motor and drive |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

自行車傾車控制系統 Leaning Control System (LCS) |

| 技術單位 |

自行車暨健康科技工業研究發展中心 Cycling & Health Tech Industry R&D Center |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

此專利傾車控制系統能大幅提升載貨自行車轉彎騎乘安全需求,使騎乘者於低速或靜止時不需觸地支撐以維持平衡,其能隨車速自動釋放或鎖定傾車功能。同時搭配超窄設計車身,可於城市內移動穿梭自如。 This patented Leaning Control System (LCS) can substantially increase the safety needs of cargo bikes when cornering. With the system automatically allow for or block tilting according to the speed of the vehicle, riders do not need to maintain balance by themselves when riding at low speed or stationary. Moreover, the system is applied on the Naro Delta Vehicle (NDV), which allows the bike to weave through in the city easily and flexibly. |

| 技術特點 |

・轉彎騎乘安全需求大增・低速或静止時無須支撐・超窄身使穿梭移動自如 ・Great increase of the safety needs・No physical support is needed when riding at low speed or stationary・Agile movement with narrow bike body |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

智慧化電動輔助跑車 Smart E-Bike |

| 技術單位 |

自行車暨健康科技工業研究發展中心 Cycling & Health Tech Industry R&D Center |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

整合控制邏輯技術,可導引騎乘踏頻至高效率區,開發智能調整人體較佳效率騎乘模式,提供電動輔助自行車系統化產品服務。 自行車電動化後擴大騎乘範圍與應用,但也帶來更多交通事故與意外傷害,運用聯網模組及E化平台,協助產業發展智慧化的安全自行車騎乘服務。 By integrating electric control logic technology, rider’s pedaling frequency to higher efficiency levels can be guided, and the intelligent and more human-efficient riding mode can be developed, providing systematic product services for E-Bike. Although some traffic accidents and injuries are caused due to the expansion of riding range and application, by applying the connected modules and E-based platforms, the intelligent and safe E-Bike riding services can be developed in the industry. |

| 技術特點 |

1)智能化調整人體較佳效率騎乘模式(2)整合騎乘動態資訊之電輔車E化平台技術 1)Intelligently adjust the human-efficient riding mode2)An E-platform technology that integrates the riding dynamic information. |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

連續式微型元件熱處理系統設備技術 Continuous Micro Parts Heat Treatment System Equipment |

| 技術單位 |

金屬工業研究發展中心 Metal Industries Research & Development Centre |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

全球首創針對高複雜結構或直徑2mm以下的零件,整合自動進料、即時監測與即時調控主加熱爐、創新油槽與收料裝置、智慧化服務等功能。 淬火油槽採取創新捕集機構設計,可完全捕集四散的微小零件,收料率100%,良率達99%,交期從30天降為2天,成本大幅降低。 This product is the World's first exclusive equipment for components with highly complex structures or diameters smaller than 2mm. It integrates functions such as automatic feed, real time monitoring and carburizing quenching furnace for real-time adjustment, innovative oil tank and collecting device, intelligent digital services, etc. The oil‑quenching tank adopts an innovative capture mechanism design to gather all scattered tiny parts to achieve a 100% collecting rate and 99% yield rate. It shortens the delivery time from 30 days to two days and massively reduces the cost. |

| 技術特點 |

・連續式熱處理・全面收料・跨產業應用 ・Continuous heat treatment・Comprehensive collection・Cross-industry application |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

集成纖維及模組化技術 RFID Yarn |

| 技術單位 |

紡織產業綜合研究所 Taiwan Textile Research Institute |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

傳統RFID標籤體積大、需外貼、不耐酸鹼和洗滌、與紡織品不相容等缺點。 紡織所開發細且柔軟的RFID Yarn®易隱藏,可織成紡織品,並通過了5大耐久性測試,拓寬應用可能性。 RFID以紗線方式,隱藏在服裝中,可以輕鬆地對衣物進行追蹤、識別和分類。 The disadvantages of traditional RFID tags, such as large size, need to be externally attached, intolerant to acid and alkali, intolerant to washing, and incompatible with textiles. The RFID Yarn® developed by TTRI is thin, soft, easy to hide, and can be woven into textiles, and has passed 5 major durability tests to broaden as many application possibilities as possible. RFID yarn can be hidden in clothing. The clothing can be easily tracked, identified, and classified. |

| 技術特點 |

・細、柔軟、易隱藏,可織成紡織品・通過紡織領域5大耐久性測試,包括:耐水洗、耐酸、耐鹼、耐高溫和耐輾壓 ・Thin, Soft, Easy to hide, It can be woven into textiles・It has passed 5 major durability tests in the textile field, including: anti-laundry, anti-acid, anti-alkali, anti-high temperature and anti-roller pressure, |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

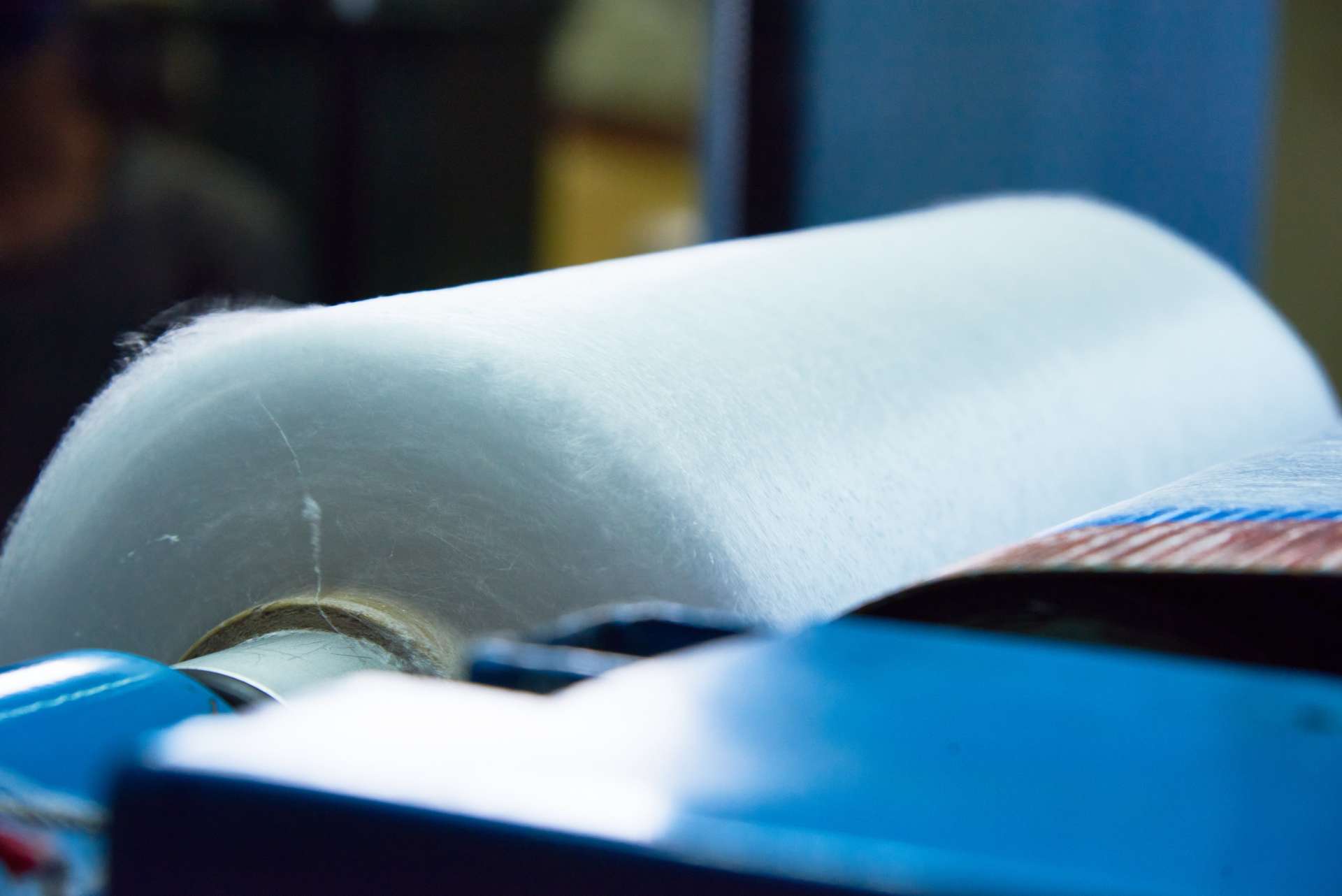

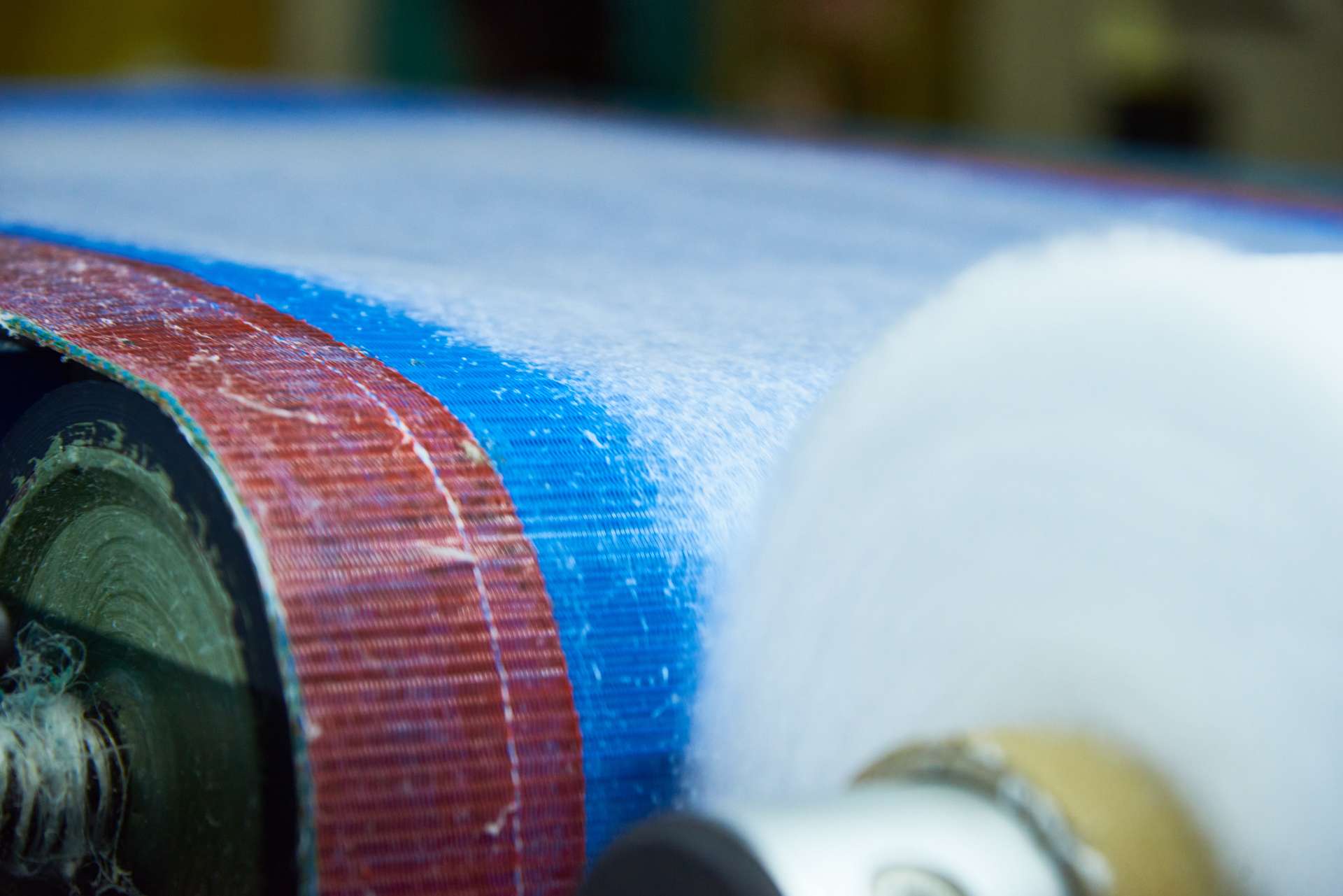

| 技術名稱 |

極細超均勻熔噴不織布技術 Ultra-fine and Extreme-uniform Meltblown Nonwoven Technology |

| 技術單位 |

紡織產業綜合研究所 Taiwan Textile Research Institute |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

突破熔噴不織布的細化與均勻性極限,直徑0.5~1.5微米纖維比例高達92%,為全球最高規格。 讓熔噴布應用從低單價的口罩濾層,轉型升級為高單價機能戶外服裝裡面的科技膜材,價值從1.5~2.5元/平方米,提升到120元/平方米以上,價值提升超過60倍。 This technology breaks through the refinement and uniformity limit of meltblown nonwovens, the fiber diameter reaches sub-micron level, and the proportion of fibers with a diameter of 0.5~1.5 microns is as high as 92%, which is the highest specification in the world. This technology transforms and upgrades the application of meltblown non-woven fabrics from a low price mask filter layer to high price functional outdoor clothing. |

| 技術特點 |

極細超均勻熔噴不織布 Ultra-fine and extreme-uniform meltblown nonwoven fabric |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

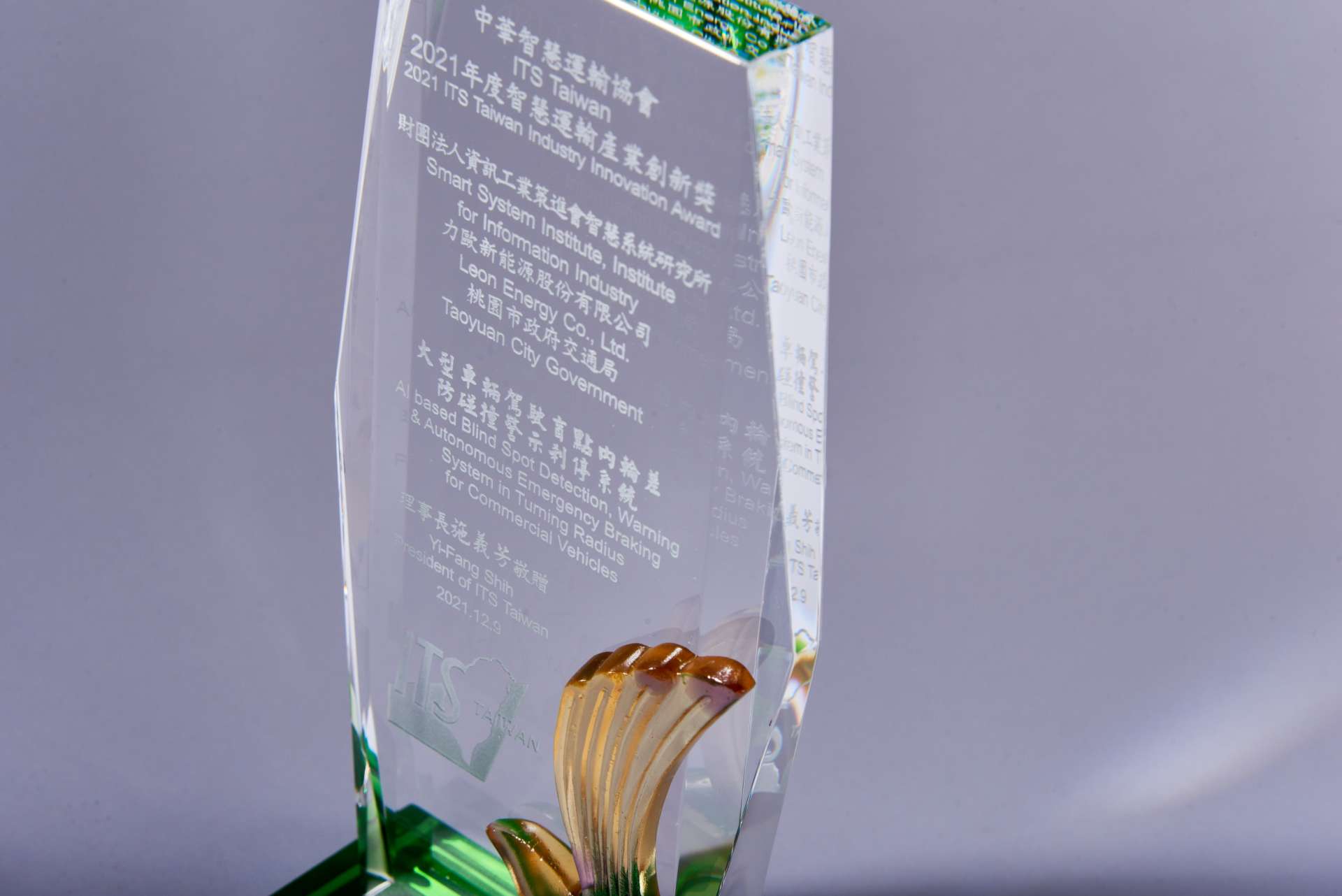

| 技術名稱 |

大型車輛駕駛盲區內輪差主動預警系統 AI based Blind Spot Detection, Active Warning System in Turning Radius for Commercial Vehicles |

| 技術單位 |

資訊工業策進會 Institute for Information Industry |

| 隸屬部門 |

軟體院 |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

本系統以AI影像辨識Formosa深度學習資料庫技術,提供大型車輛駕駛視線死角與內輪差之安全警示服務,有效避免行車事故發生。技術特色:車輛行進動態調適警戒範圍、根據距速緊急程度示警、有效警示二輪車、行人及騎士類別。 Blind Spot and Turning Radius are common cause of large vehicle accidents. The driver only have 1 second to react when large-vehicle passing through the intersection of object approaching in dangerous, The system is AI-based blind spot detection, active warning to driver in turning radius for large-vehicles. Feature: dynamic adapting the warning range of the vehicle, according to the emergency level of the driving behavior, identified two-wheeled vehicles, pedestrians and riders. |

| 技術特點 |

・AI精準辨識交通物件・各種天候情境穩定示警・適應台灣混合車流環境 ‧AI traffic objects detection accurately‧Stable warning in various weather situations‧Adapt to the mixed traffic environment in Taiwan |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

線上半導體2nm製程關鍵尺寸X光量測設備 In-line Semiconductor N2 Process Critical Dimension X-ray metrology Tool (XRCD) |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

量測中心 |

| 團隊名稱 |

NanoSeeX NanoSeeX |

| 技術 Slogan | |

| 技術簡介與應用 |

半導體製程進入2奈米節點,GAA製程面臨挑戰,如新材料、需精密解析度監控以確保良率等。本設備以X光為基礎,穿透多層環繞式閘極結構,以原子級解析度監控關鍵尺寸,減少90%量測時間,為台灣自主開發之線上量測2nm製程關鍵尺寸設備, 2025年市場預計1.3億美元,年成長率達36.8%。 In the 2nm node semiconductor process, GAA three-dimensional structures face challenges such as new materials and require super high resolution monitoring to ensure process yields. The team develops this 2 nm node front-end metrology tool based on X-ray technology. The XRCD metrology tool measures multilayer GAA structures and monitors critical dimensions with atomic-level resolution, reducing measurement time by 90%. The target market includes foundry and memory below N2 process node. The market is expected to be USD 130 million in 2025, with an annual growth rate of 36.8%. |

| 技術特點 |

1. X光反射式量測技術2. 應用於半導體2奈米製程前段3. 減少90%量測時間 1. Reflexive X-ray measurement2. Applicable for 2nm semiconductor front-end process3. 90% reduction in measurement time |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

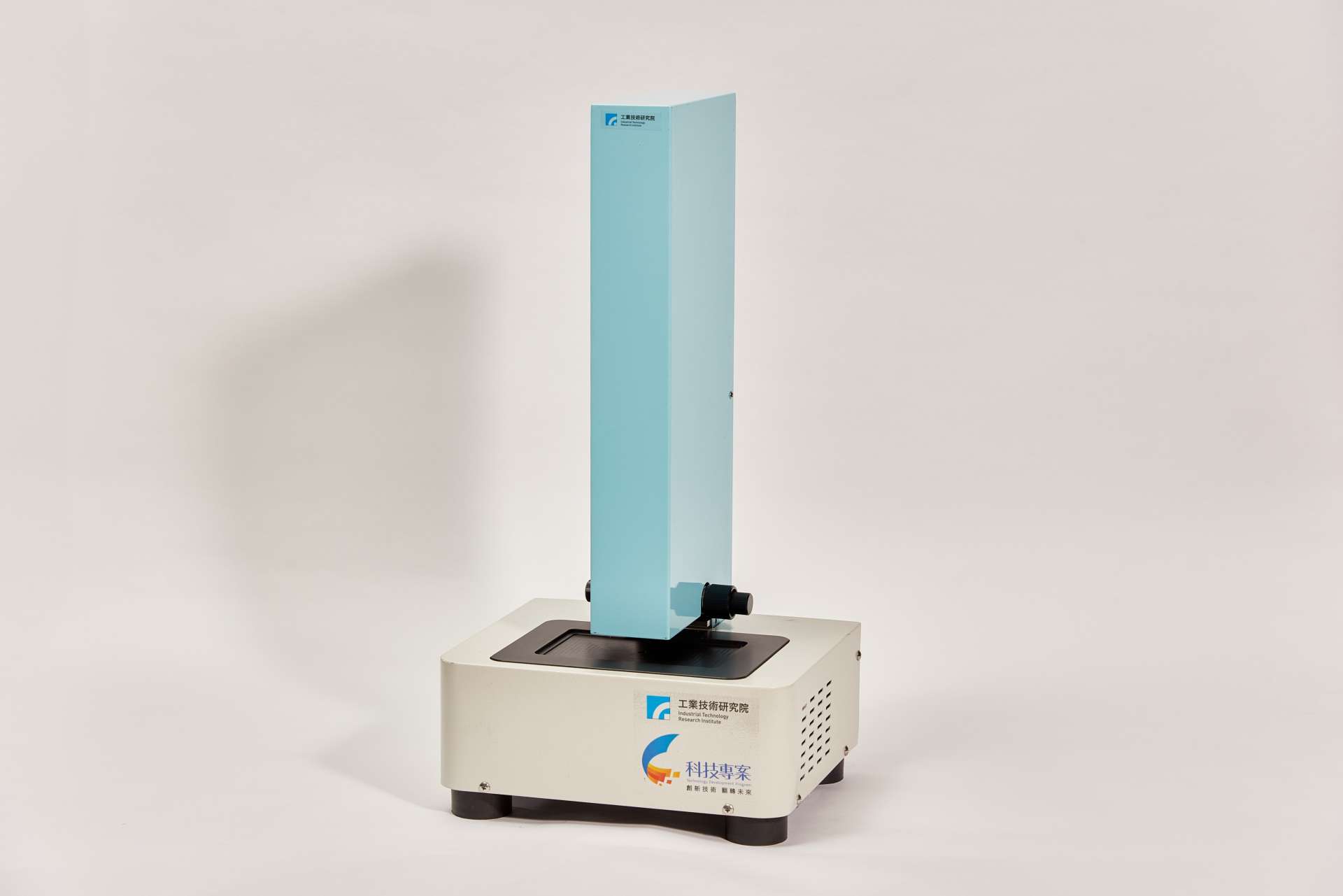

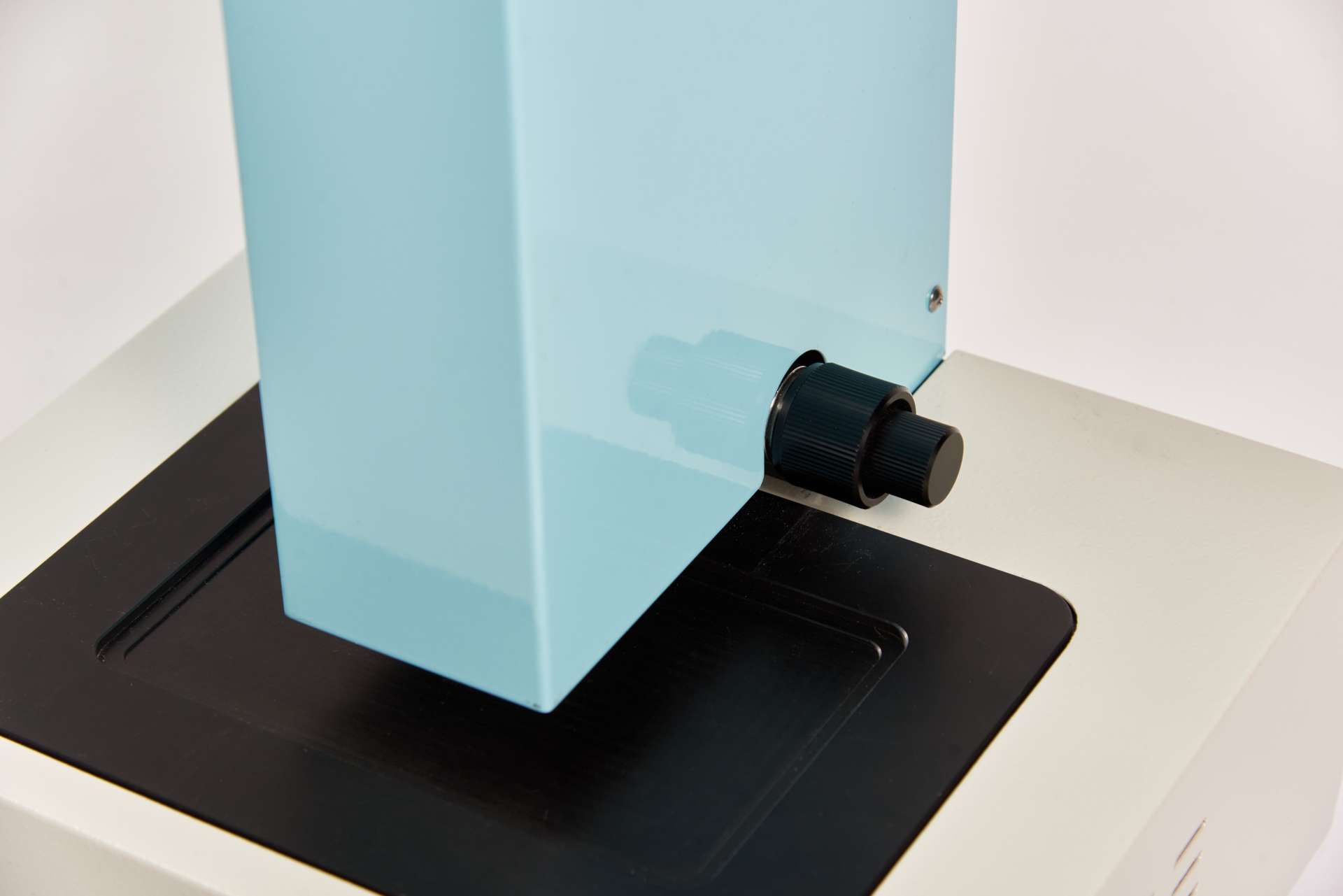

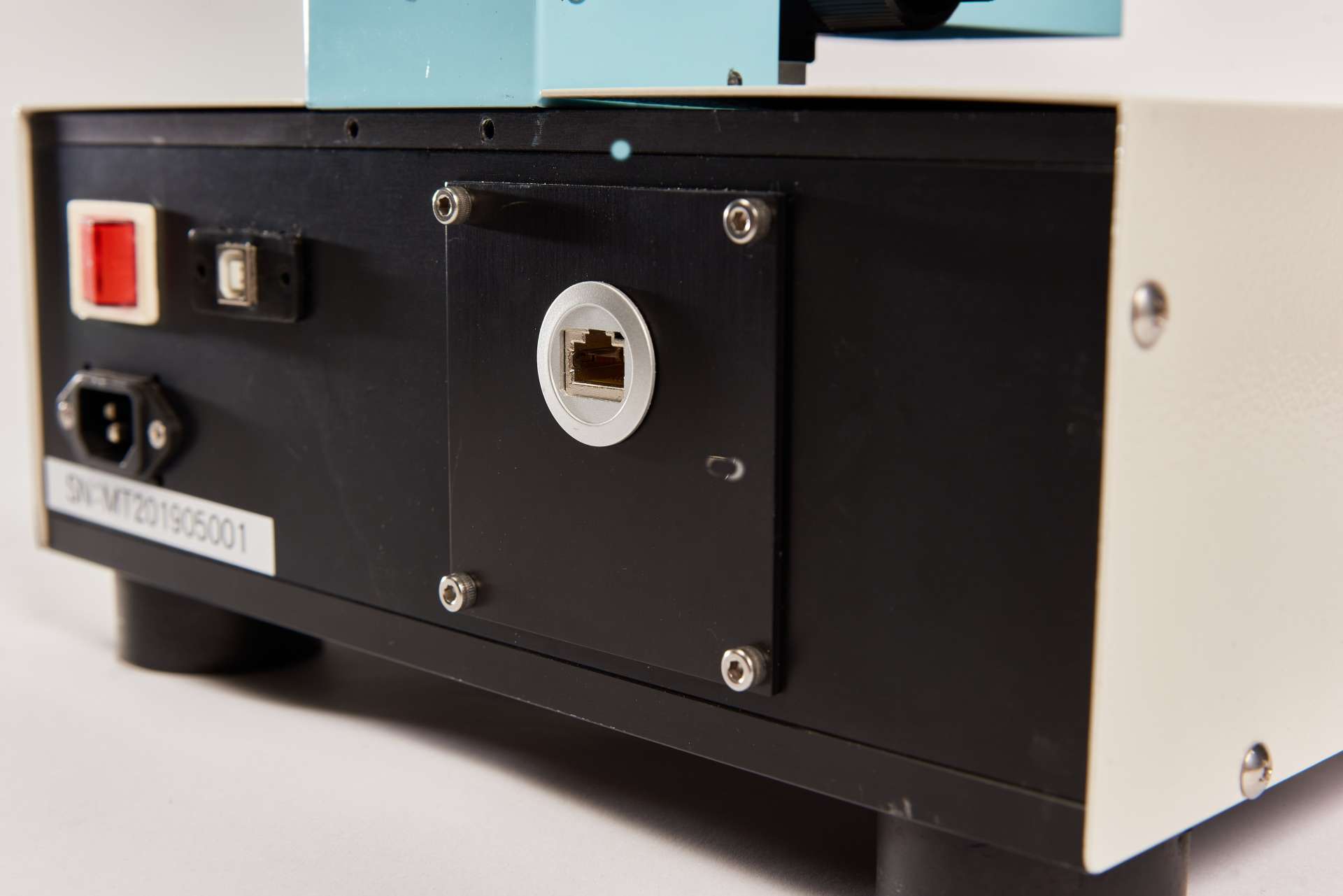

| 技術名稱 |

On-Line高精度雷射測厚儀系統 On-Line High Precision Laser Thickness Gauge System |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

產服中心 |

| 團隊名稱 |

智升科技 AI-UP |

| 技術 Slogan | |

| 技術簡介與應用 |

「雙雷射晶圓Warp / TTV/ Thickness 檢測設備」具有 (1)精準度高、(2)抗震動、(3)穩定性高、(4)操控性好、(5)快速檢測、(6)防止晶圓破損,全部需求一次逹成。檢測速度快速,多點測量設定,提升晶圓製造之品質,降低晶圓減薄業者所需之晶圓檢測設備成本。可測量材料包括金屬、非金屬、晶圓等材料。 「 Dual Laser Wafer Warp / TTV / Thickness Inspection Equipment 」 has (1) high accuracy, (2) anti-vibration, (3) high stability, (4) good controllability, (5) fast inspection, (6) Prevent wafer breakage. All needs to be completed at one time. Fast inspection speed and multi-point measurement settings improve the quality of wafer manufacturing and reduce the cost of wafer inspection equipment required by wafer thinning operators. Measurable materials include metals, non-metals, wafers and other materials. |

| 技術特點 |

1 可量測精度達1μm2 無輻射危害3 產線上連續量測 1. measurement accuracy: 1 um2. No rediation3. On-line continuous measurement |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

高強度航太鋁合金鑄件之低壓鑄造技術 Low-pressure Casting Technology for High Mechanical Property Aerospace Aluminum Casting |

| 技術單位 |

天陽航太科技股份有限公司 AvioCast Inc. |

| 隸屬部門 | |

| 團隊名稱 | |

| 技術 Slogan | |

| 技術簡介與應用 |

1. 航太鑄件傳統的重力澆鑄,易產生充填流動、捲氣夾渣之缺陷,低壓鑄造技術有效解決該問題,良率大幅提升,尤其是大型複雜件。 2.低壓鑄造有助良率之提升,帶動生產成本降低,並提高市場競爭力。且強化天陽於精密及砂模鑄造之能力,於國際間的接單實力大增。 1. The conventional dynamic pouring of aerospace castings is easily to cause the slag and inclusion. Comparing with conventional process, Low pressure casting technology is more stable and reliable with higher yield rate, especially for large and complex parts. 2. Low pressure casting can improve yield rate, reduce production costs, and enhance market competitiveness. In addition, strengthen the ability in making investment and sand casting, and recive more orders. |

| 技術特點 |

・鑄件高強度且型式複雜・良率高品質穩,製程安全・提升國際市場競爭力 ・Large and Complex casting with high mechnaical property ・Low process variation. Stable quality・enhance international market competitiveness |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|

| 技術名稱 |

智慧機械雲平台與地端標準執行環境聯網技術 The Intelligent Cloud Platform for the Machinery Industry and on-premise Taiwan Machinery Standard R |

| 技術單位 |

工業技術研究院 Industrial Technology Research Institute |

| 隸屬部門 |

智機中心 |

| 團隊名稱 | |

| 技術 Slogan |

發展智慧機械解決方案,建置智慧機械雲產業生態體系。 To develop intelligent machinery solutions and establish an ecosystem for the Intelligent Cloud Plat |

| 技術簡介與應用 |

智慧機械雲是一個標準執行環境,協助不同單位開發的智能化軟體協同共存,擴大應用範圍。它採用國際標準通訊介面和資訊模型技術,幫助產業快速接軌國際市場。並建立專為機械產業設計的軟體市集,提供符合國際級資安需求的零信任資安防護系統。 The Intelligent Cloud Platform for Machinery Industry offers TMSR, a standardized execution environment enabling collaboration of intelligent software, expanding its application scope. It integrates international communication interfaces and modeling techniques to align industries with the global market. It establishes a machinery industry marketplace, featuring a secure cybersecurity system meeting international standards. |

| 技術特點 |

建立SMB標準執行環境打造機械產業電商平台五大產業導入智慧製造 Establishing an SMB standard execution environment.Building an e-commerce platform for the machinery industry.Introducing smart manufacturing into five major industries. |

| YOUTUBE | 觀看影片 |

| 相關照片 |

|